THERMODYNAMIC TECTONICS

CATEGORY: Architecture (Research - Graduate Thesis)

LOCATION: Torrance, CA

TYPE: Residential

PROGRAM: Single Family

HEIGHT: 1 story; 12 feet

AREA: 1,400 sf

DURATION: 8 months

DESCRIPTION:

Matter and energy have fueled the growth of modern society since the world’s earliest civilizations. However, society’s organization of these natural resources has recently come into serious question due to increasing evidence of the declining health of human and ecological systems. At the center of this issue, buildings and cities consume most of the world’s material and energy resources while emitting a majority of greenhouse gases. This graduate thesis project questions conventional concepts in architectural design as well as common construction methodologies by investigating how different building assemblies use material and energy over time.

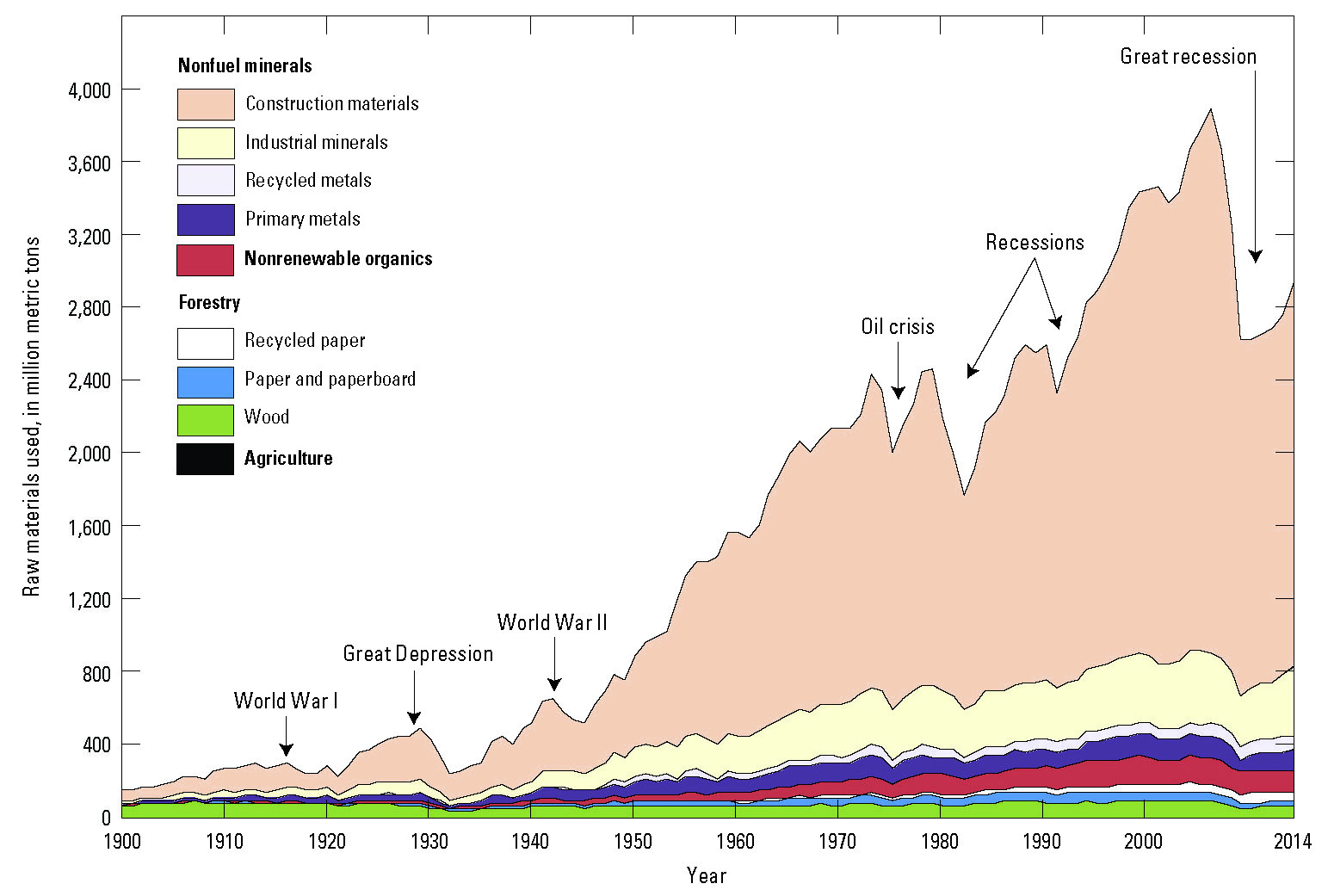

U.S. material use (1900-2014)

In the United States alone, a primary consumer of the world’s raw material and fossil fuels, construction materials accounted for almost three-quarters of the nearly three billion metrics tons of raw material used in 2014 as illustrated in the graph above. Every year, approximately 160 million tons of building material ends up in landfills as construction and demolition waste. That equates to roughly one Empire State Building being thrown away every single day for an entire year ((1.60 x 10^8 tons of C&D waste per year) / (3.65 x 10^5 tons Empire State Building mass) / (365 days/year) = 1.2 Empire State Buildings worth of C&D waste per day). Moreover, building construction and operation consumes 36% of all global energy while emitting nearly 40% of all CO2 emissions every year, more than all global transportation or industrial activities (Image Source: U.S. Geological Survey).

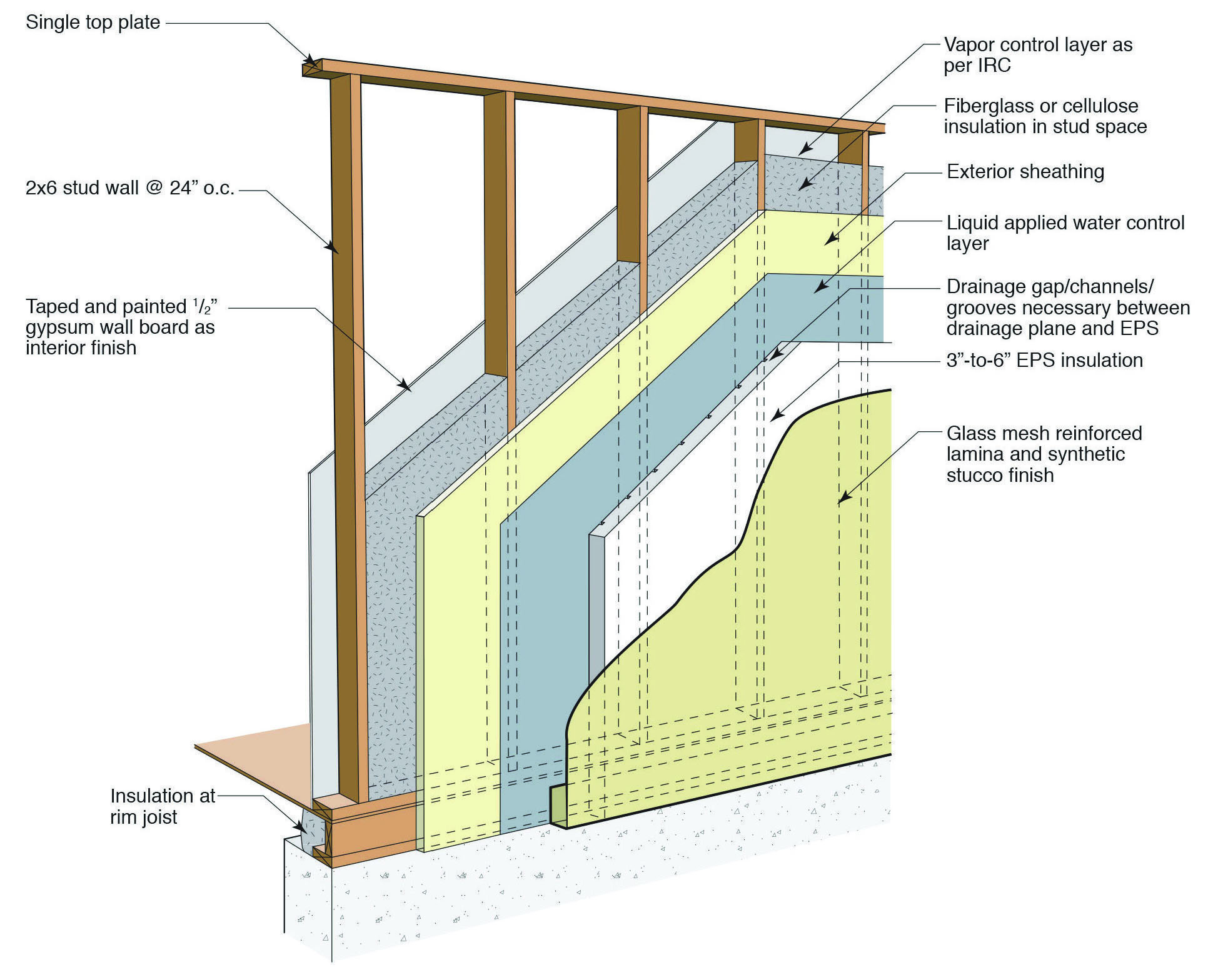

Conventional Construction

Construction today follows a complicated logic of layering and fixing different building materials to one another as demonstrated above. Buildings, therefore, become static and impermeable to necessary changes when they are comprised of multiple layers of building materials that are permanently fixed– cast, glued, welded, or irreversibly adhered– to each other. Many of these new “modern” materials such as air and vapor barriers, synthetic membranes, insulation, and glass are extremely thin and lightweight, which usually requires attaching them to additional support materials in building assemblies. This logic of layering various building materials to one another only further complicates the design and construction process (Image Source: Building Science Corporation).

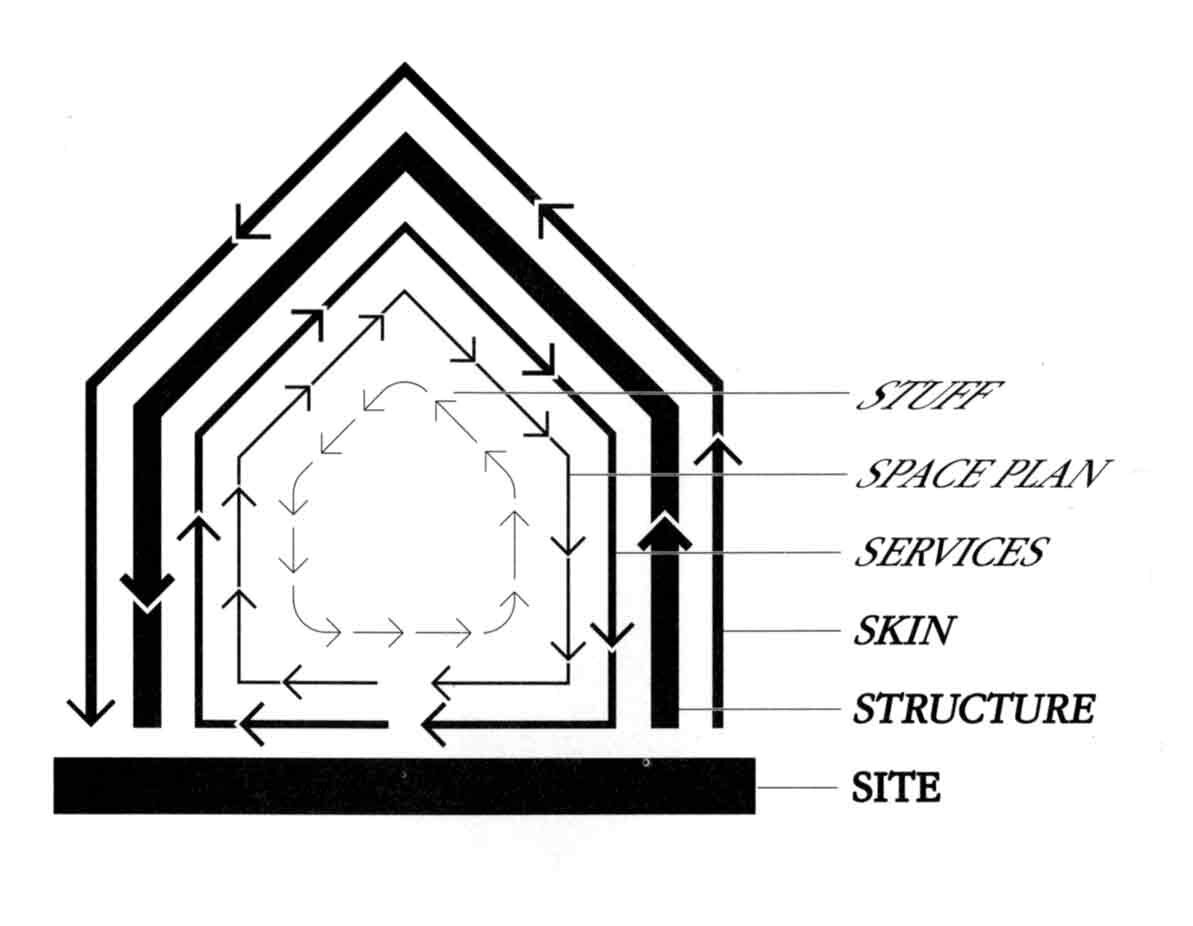

Shearing Layers

Moreover, buildings themselves are layered into different elements such as structure, skin, mechanical services, and interior space plan. Each element is usually then further sub-layered and permanently fixed to the other elements during construction producing a complex hierarchy of systems and subsystems in buildings. Architect Frank Duffy explains that “there isn’t such a thing as a building. A building properly conceived is several layers of longevity of built components” and that “the unit of analysis [shouldn’t be] the building, it’s the use of the building through time. Time is the essence of the real design problem” (as quoted in Brand 1994, 12-13). Stewart Brand refers to these building systems as “shearing layers” because, in reality, buildings are continually tearing themselves apart due to the varying lifespans of different building materials. While it is important to recognize that buildings are built as permanently fixed multi-layered objects, it is more meaningful to understand that they are intentionally designed this way. Building design inherently follows one of two fundamentally different conceptual frameworks: buildings as closed static systems or building as open dynamic systems (Image Source: Brand 1994, 13).

Closed Static Systems

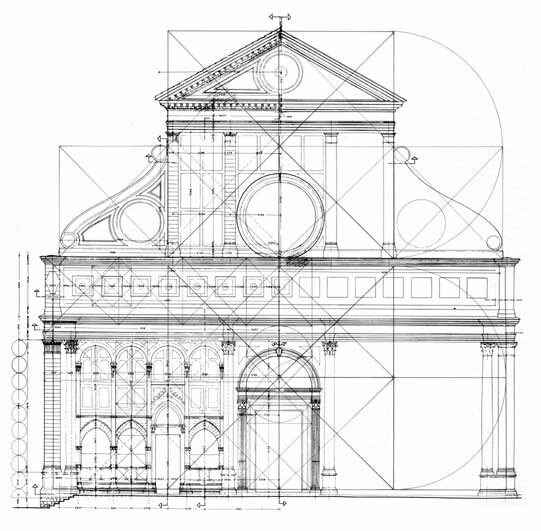

Since architecture’s conception from an ancient building process to a highly refined craft, buildings have mainly been conceived as closed static systems impervious to the changing conditions around them. From Vitruvius in the 1st century to early 20th century Modernists and to many architects today, buildings continue to be designed on faulty theoretical foundations of form, fixity, and flawlessness (For a description of how modern architectural photography further enabled this way of thinking see Mostafavi, M., & Leatherbarrow, D. 1993. On weathering: The life of buildings in time. Cambridge, Mass.: MIT Press. p.82; Also Brand, S. 1994. How buildings learn: What happens after they're built. New York, NY: Viking. p.55). As architectural historian Daniel M. Abramson points out in Obsolescence, these ways of thinking have always been ingrained in architecture:

“Aesthetically, classical design, the dominant Western tradition since the Renaissance, strove for ideals of fixity and permanence. The Italian theorist and architect Leon Battista Alberti, in his seminal fifteenth-century treatise, defined formal perfection as ‘that reasoned harmony of all parts within a body [image above], so that nothing may be added, taken away, or altered, but for the worse.’ According to Alberti’s prescription, a building was beautiful only when it appeared unchangeable and finished in time. Architects followed this vision for centuries” (Abramson 2016, 12).

Many architects continue to envision and design buildings as objects perfectly fixed and finished in time. This is also precisely why most buildings today reach their demise by demolition; they exhibit too much stasis and permanence and cannot adapt– to different functions, personal styles, market conditions, technologies or changes in the climate. While the previous sections demonstrate how buildings are designed and built as closed static systems, in reality, buildings are– and always will be– open dynamic systems; they essentially only exist because they are open and dynamic. (Image Source: Santa Maria Novella)

Open Dynamic Systems

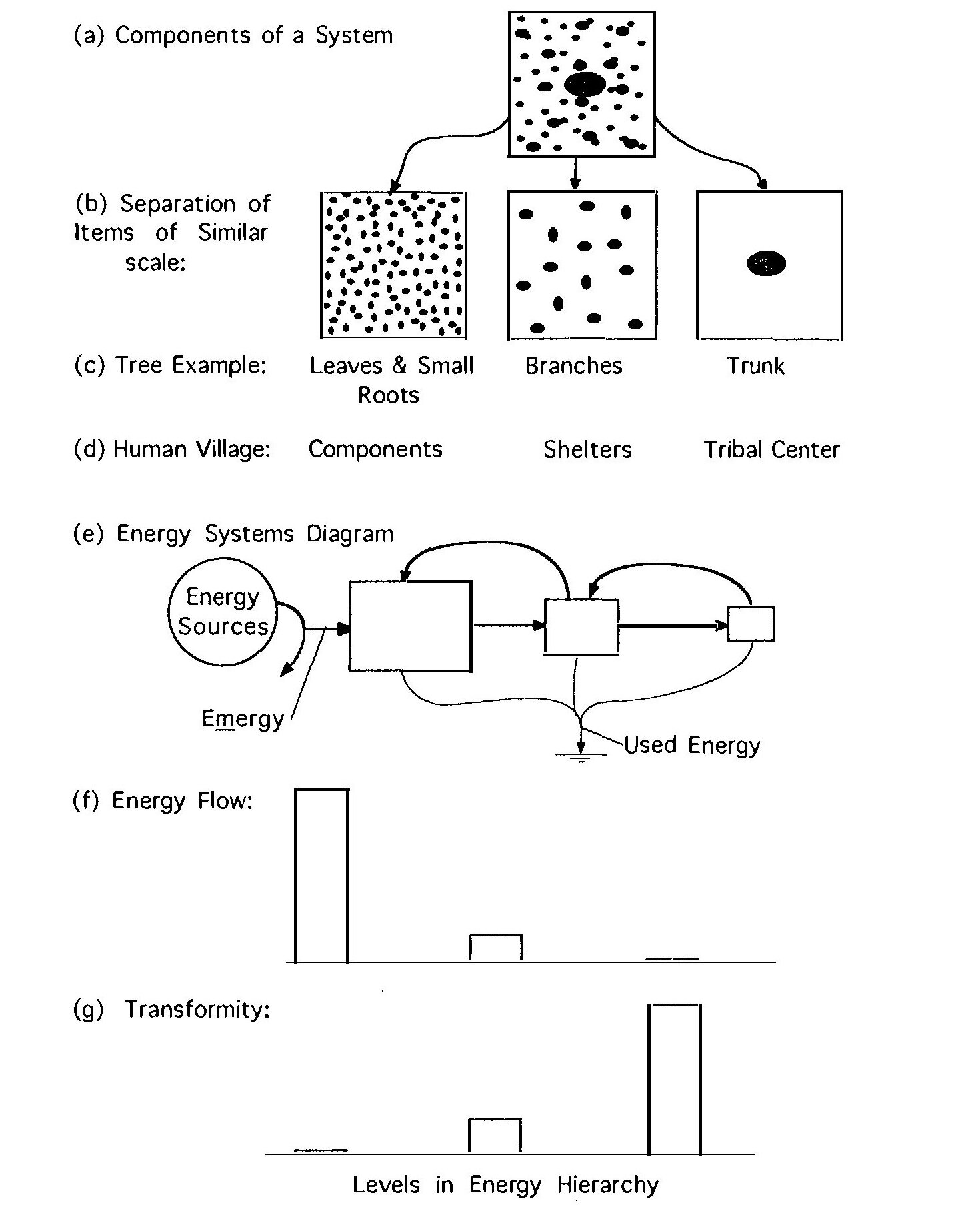

As hierarchical organizations of different elements that exchange matter and energy with their surrounding environments, buildings are, by definition, open dynamic systems; like all living organisms, they fundamentally require a constant influx of material and energy from the outside world for survival. Howard T. Odum, the pioneering system ecologist, reminds us that whether in nature’s construction of a tree or in society’s construction of a city, the transformation of matter, energy, and information determines the “main features of successful self-organization that will emerge,” and that in all energy systems, “structures and processes [develop] on each scale of size and time, transforming energy of one scale to make the products for the next.” Consider his simple energy hierarchy diagram of a tree (a,b,c) and of a human village (d) above. Leaves and roots transform lower quality energy from the sun, wind, and soil into higher quality organic nutrients used by the branches and tree trunk for growth (e). In return, the tree trunk and branches structurally support the smaller leaves and roots. Similarly, in the human village, inhabitants collect dispersed lower quality material and food energy from the forest to construct shelters and a tribal center for the village. The higher quality shelters and tribal chief reinforce these actions by providing protection and controlling family patterns which in turn control forest harvesting processes that generate food and materials for the growth of the village. These reinforcements or feedback pathways play a significant role in selecting the processes that contribute to the system enabling adaptations and evolution to occur dynamically over time. As the available energy in both systems decreases (f), the quality of the energy (g) increases (See First and Second Law of Thermodynamics, also known as the “Law of Conservation” and the “Law of Entropy” for how energy quantities and energy qualities work in energy systems). The buildings and cities we live in today operate based on these exact same principles and should therefore be meaningfully designed with them in mind. (Image Source: Odum, Howard T. “Material circulation, energy hierarchy, and building construction”)

Alternative Building Methodologies

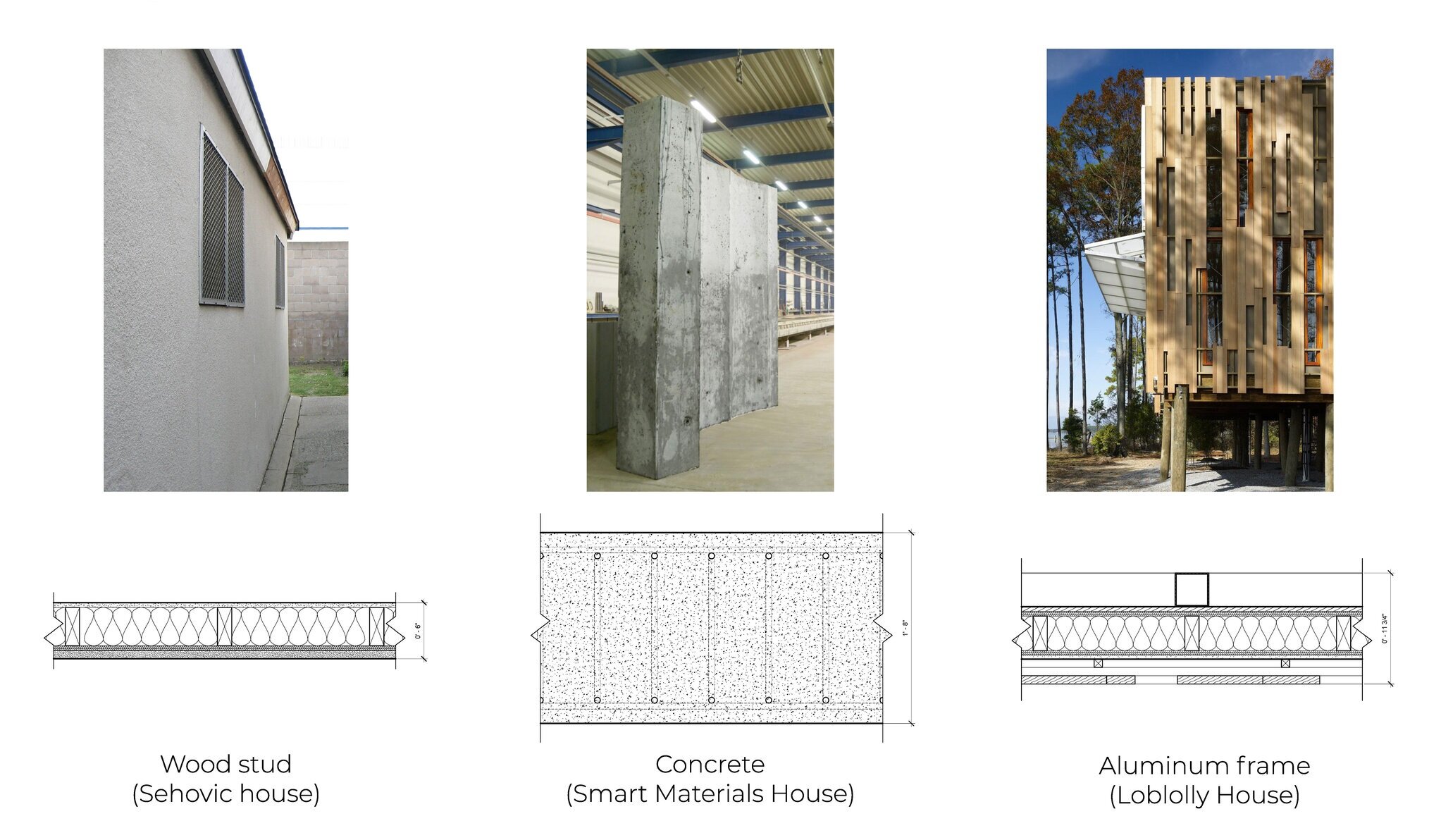

The architecture firm KieranTimberlake in recent years has reintroduced the idea of industrial manufacturing into architecture to allow for buildings to be made of interchangeable components that can easily be changed and adapted. Their partnership with LivingHomes, a Los Angeles-based design and construction company, has created a series of prefabricated residential modules that offer the option to grow or shrink parts of the building within an aluminum structural framing system illustrated above. KT developed this methodology from the Loblolly House and transferred it to the Cellophane House which were both manufactured off-site and offer the possibility for easy assembly and disassembly at the end of each building’s life. (Image Source: KieranTimberlake).

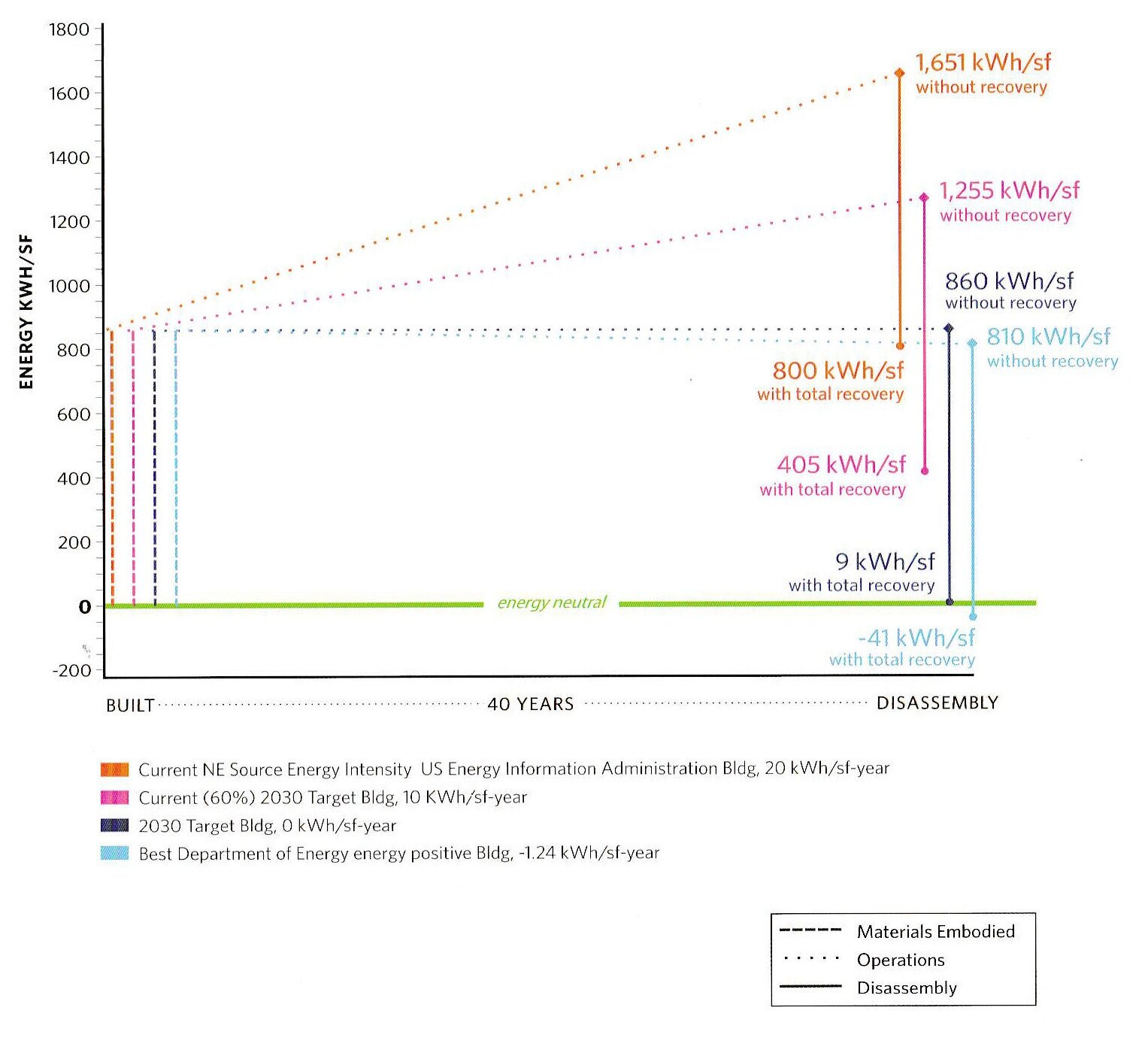

Material, Energy, and Building Life-cycles

The graph above conceptually demonstrates the life-cycle of four buildings over a 40-year lifespan from a material and energy point of view. Note the potential to achieve energy neutrality using building disassembly and material recovery (Image Source: Kieran and Timberlake 2011).

Similarly, John Fernandez, an architect and Director of the Urban Metabolism Group at MIT, proposed the idea of planning obsolescence into architecture. His “Theory of Diversified Longevity” suggests to purposely vary the lifetime of building elements to allow for changes to incrementally happen over time. He argues that this offers a greater range of flexibilities, embodied energies, costs, and durabilities in buildings (Fernandez 2002, 15). The Quinta Monroy and Villa Verde housing projects by Chilean architectural office Elemental serve as built examples of a similar strategy.

While design for disassembly (DfD) and material recovery practices are relatively new in the building industry, they have been around for some time in other industries such as product design and electronics. Several publications have been written on various DfD topics ranging from connections (Jeandin and Mascle 2016), evaluations metrics (Mayer and Bechthold 2017), sequencing (Cappelli et al., 2007), urban scale analysis (Crowther 2016) and even national building standards (Clapham et al., 2008).

Hypothesis and Objectives

Envisioning, designing, and constructing buildings as closed static systems will only produce more challenges in the dynamically evolving culture, climate, and technology of the 21st century. Buildings must be thought of less as fixed objects in time and more as open systems of dynamically flowing matter and energy. This project hypothesizes that converging lightweight multi-layered assemblies into monolithic high thermal mass materials can significantly improve material and energy flow through buildings over time. By evaluating these types of assemblies based on their overall embodied energy, impacts on operational energy performance, and potentials for material recovery, this thesis seeks to provide a framework for architects to be able to better analyze, understand, and ultimately design individual buildings and building processes that dramatically improve natural resource use and, by extension, the dynamics of large-scale socio-ecological systems.

Methodology

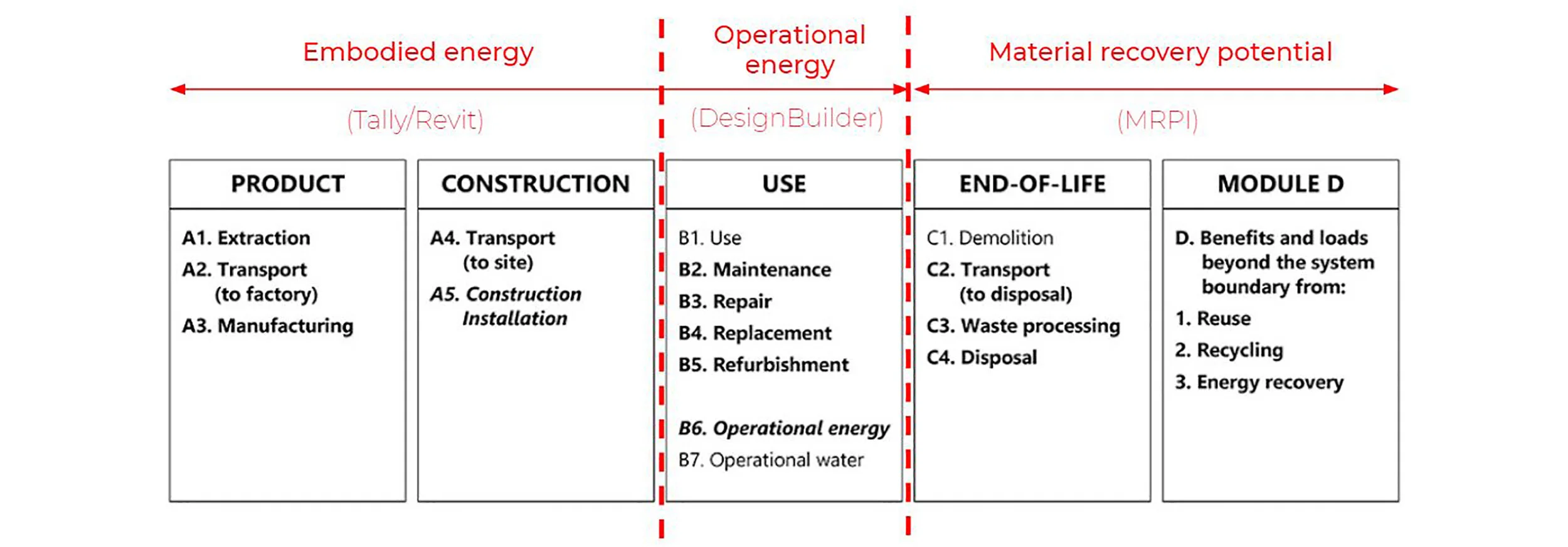

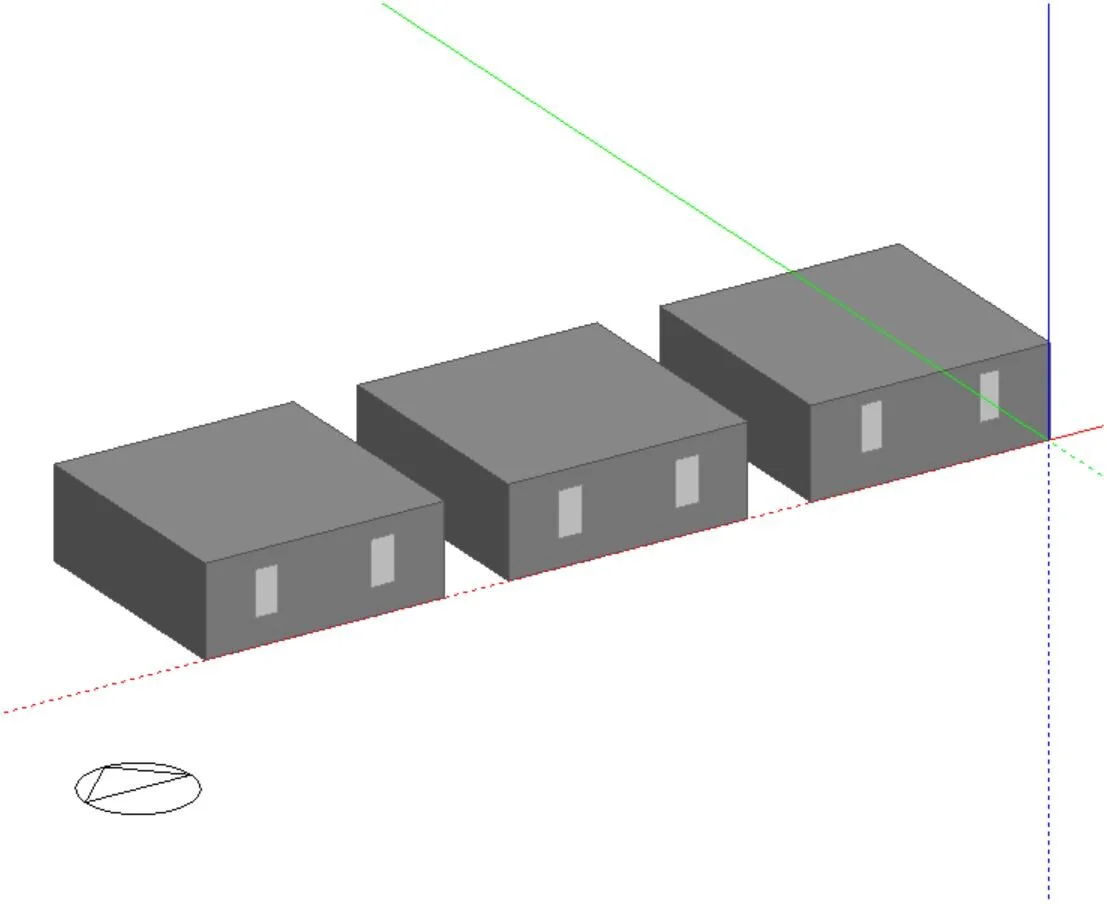

The methodology for this research consisted of analyzing the material embodied energy, operational energy use, and material recovery potential for the three main phases in a building’s lifetime: 1) production and construction, 2) use and operations, and 3) end-of-life. The figure above illustrates these stages with the calculation methodology and boundaries shown in red which are further discussed in the sections below.

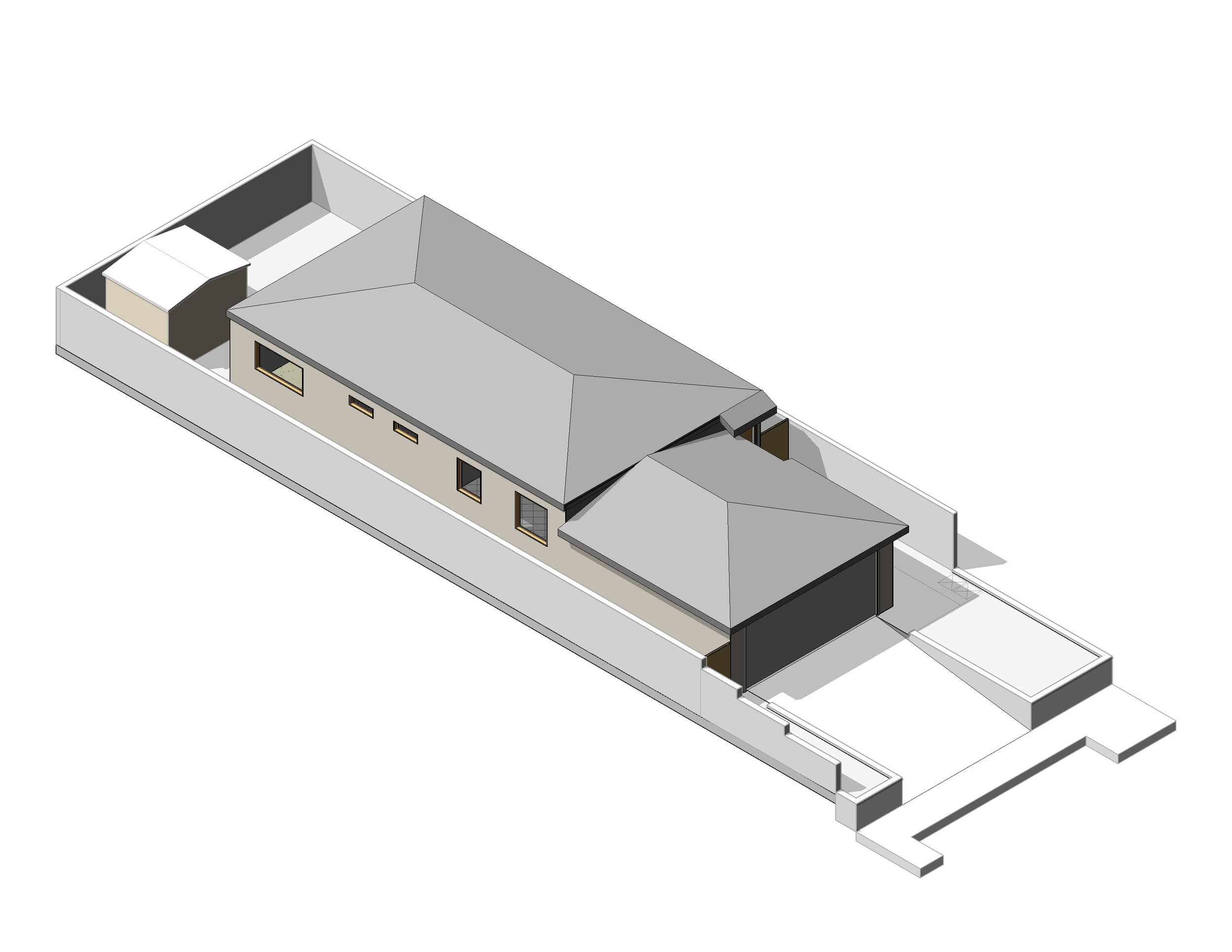

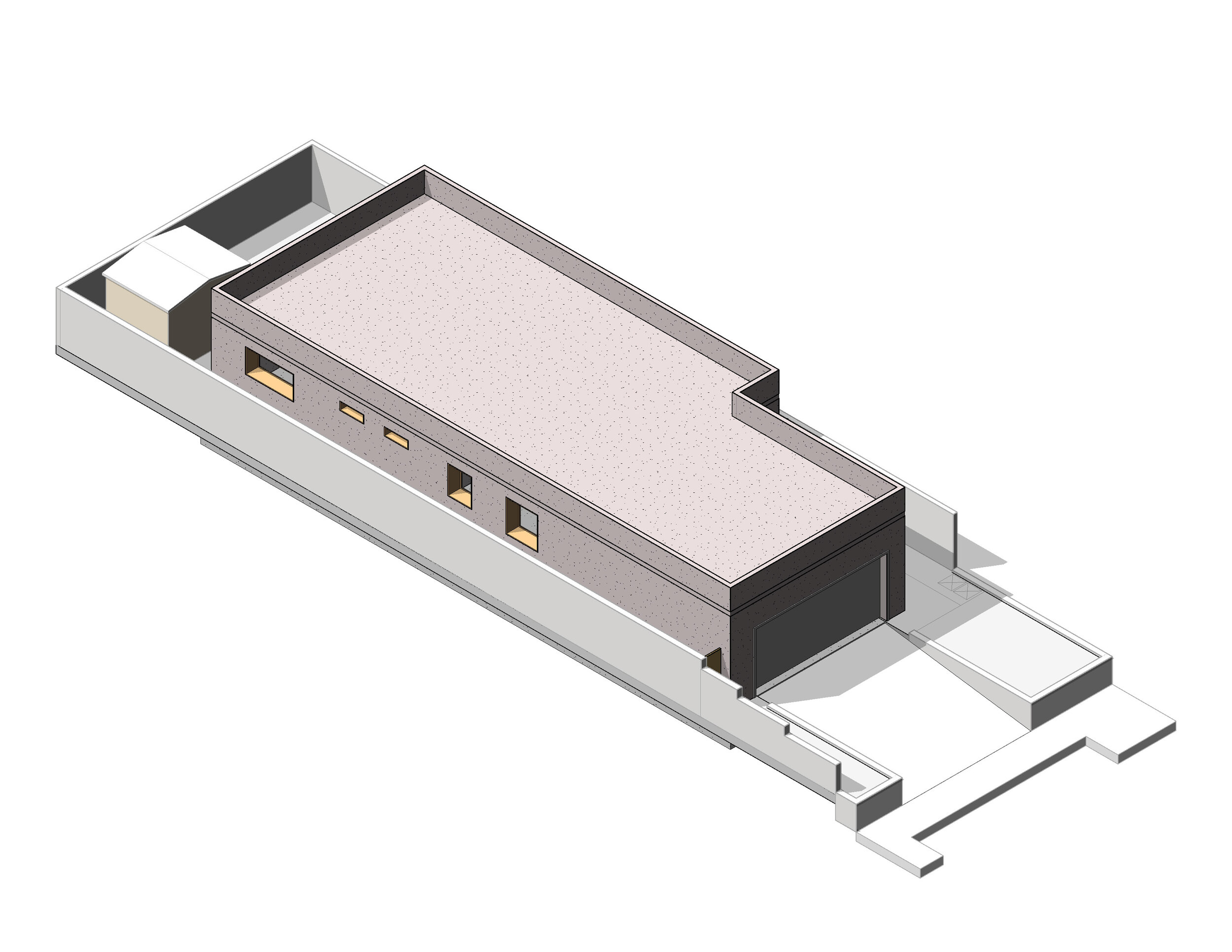

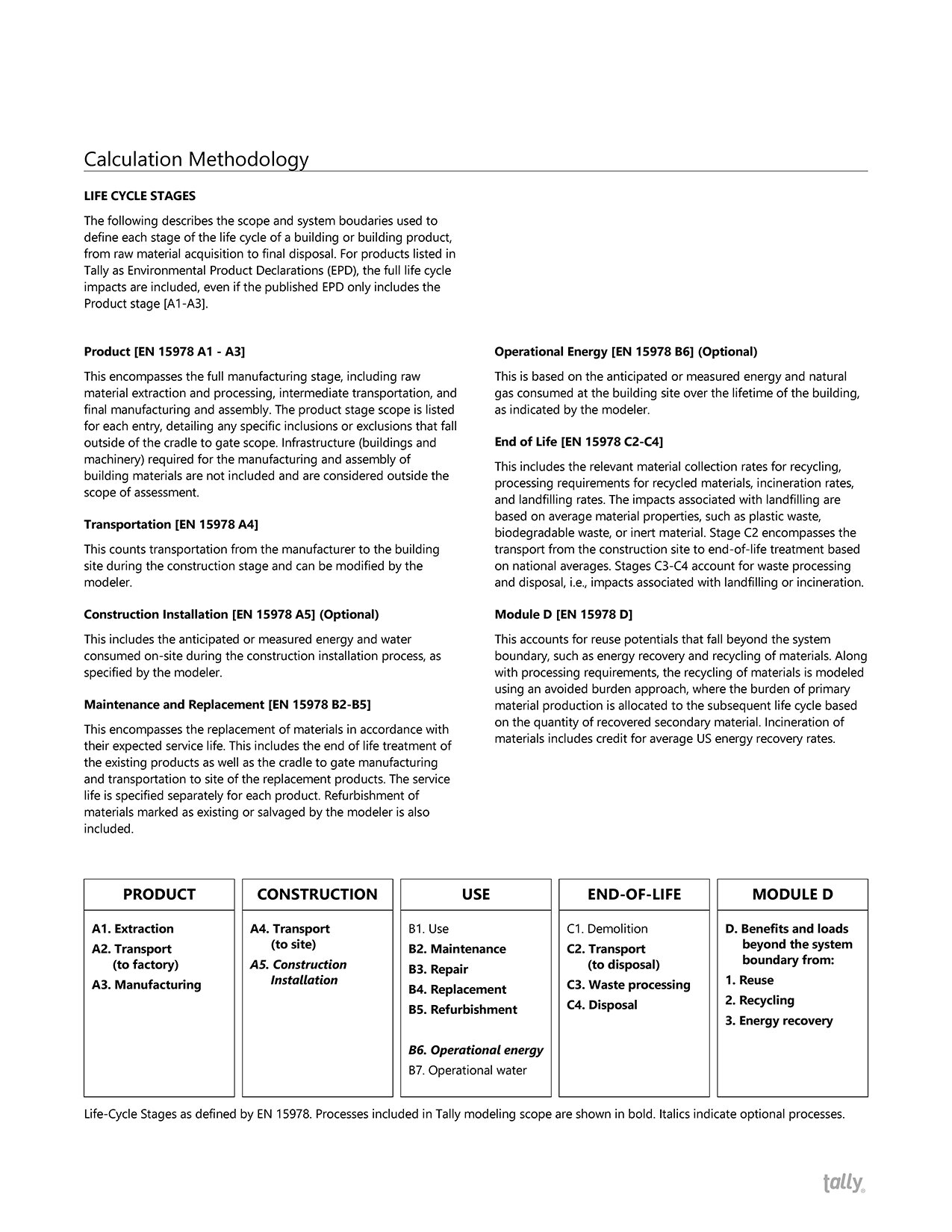

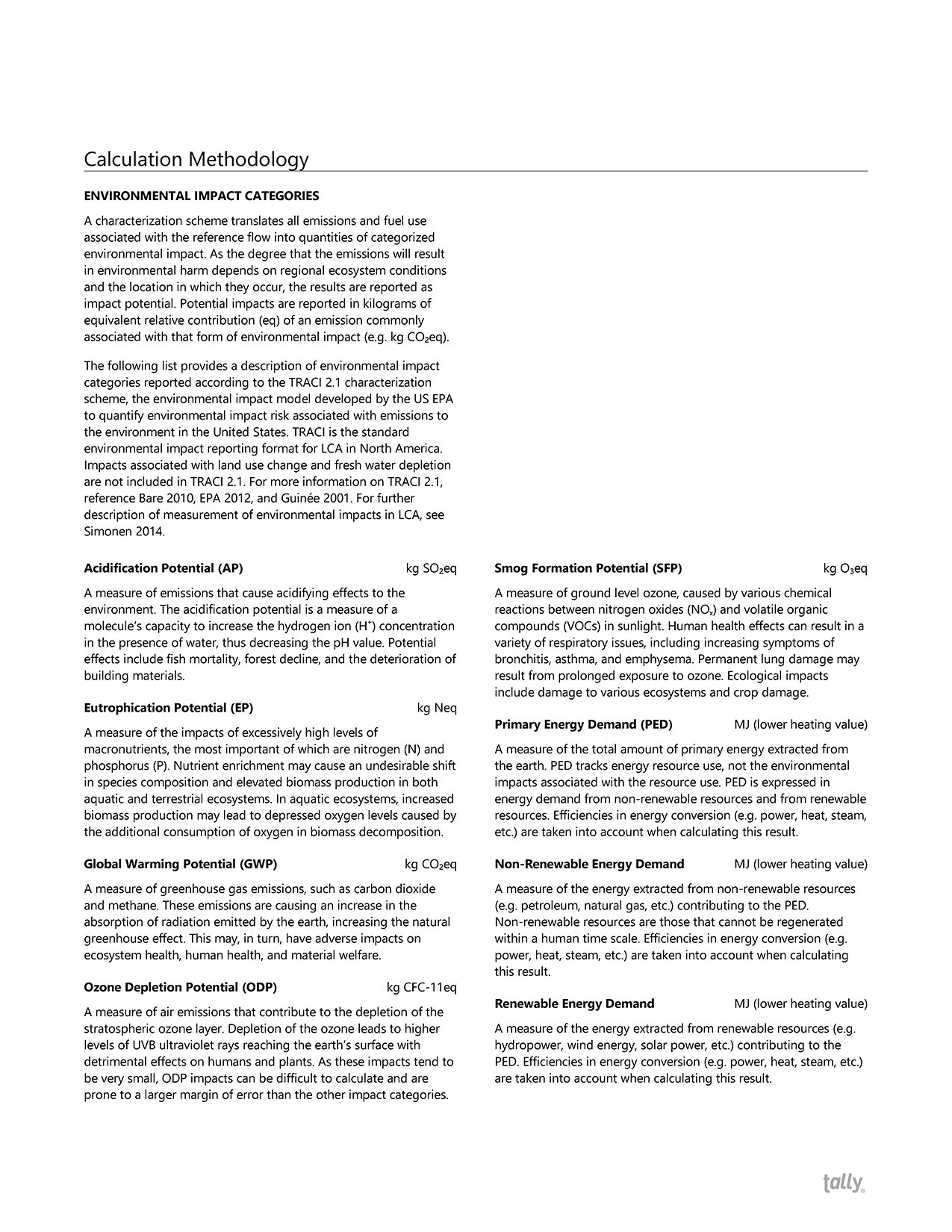

This methodology was applied to the three existing facade assembly systems shown in the previous image and two versions of the same building. The Sehovic House represents the first assembly– a typical site-built North American residential construction system comprised of conventional wood stud framing and an exterior stucco finish. The second assembly uses a lightweight prefabricated structural concrete panel utilized in the Smart Materials House. The third assembly– an aluminum structural system with factory-built wood enclosure panels and a rainscreen layer– is used in the Loblolly House. These three assembly systems were chosen precisely because of their vastly different design approaches to material use and assembly layering. The existing Sehovic house and a concrete version of the Sehovic house utilizing the wall assembly of the Smart Materials House served as the two test buildings. The sections below further describe the processes used to evaluate the facades and buildings.

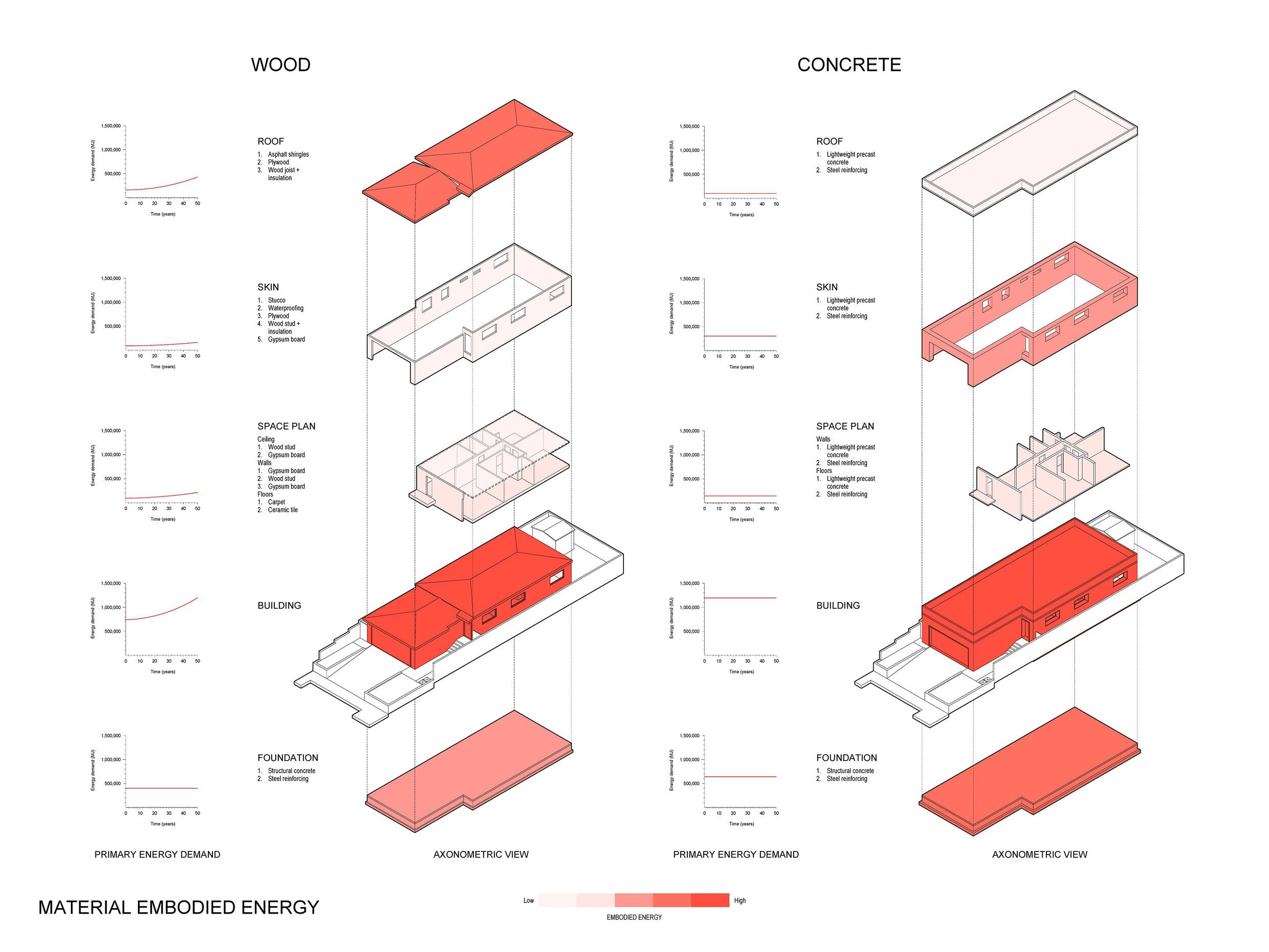

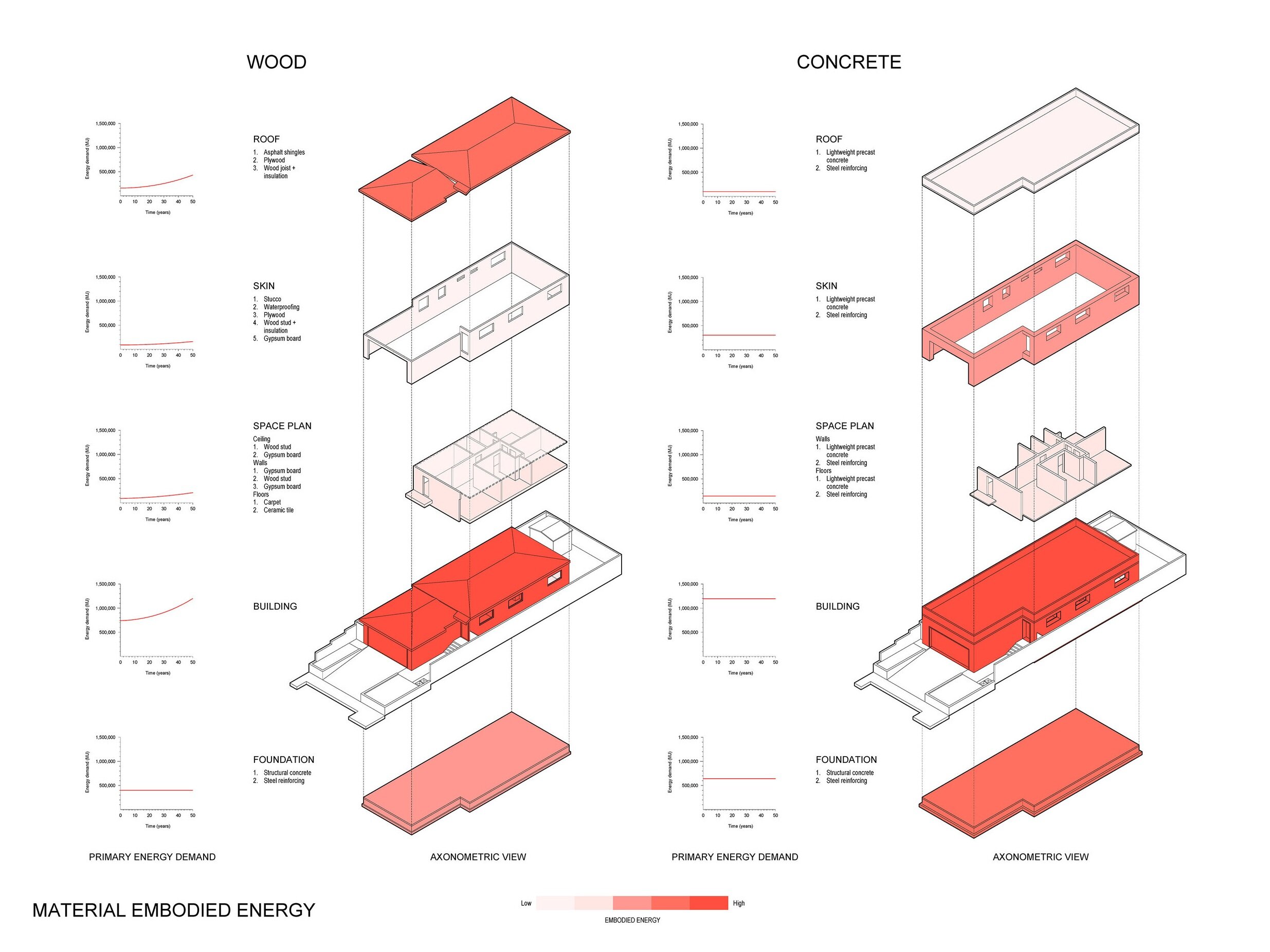

HIERARCHY OF MATERIAL EMBODIED ENERGY

The facade assemblies and buildings were first drawn as 3D building information models (BIM) using Autodesk Revit 2018. See Appendix 1 for images of the 3D facade and building models. Properties for each assembly material were assigned and evaluated using Tally 2019, a parametric life-cycle assessment (LCA) plug-in tool for Revit. This provided embodied energy data for the production, construction, and use stage of each facade and building over a typical building lifespan of 50 years.

The material embodied energy at the building scale was grouped into roof, skin, space plan, and foundation in an attempt to investigate Brand’s shearing layers concept. While the roof could be considered as part of the building’s exterior skin, it remained separate in the building study for consistency with the facade experiments. Walls, floors, and ceilings represented the interior space plan. Since the structure was mainly embedded within the skin in both buildings, only the structural foundation could be evaluated on its own. The embodied energy of services was not considered since no mechanical heating and cooling system exists in the Sehovic house except for a small gas radiator which was considered negligible. Site and stuff (i.e. furniture, equipment, etc. as per Brand’s layering concept) were also omitted as they fell outside the main scope of analysis. Windows, doors, and stairs were also considered negligible for this particular building and therefore omitted.

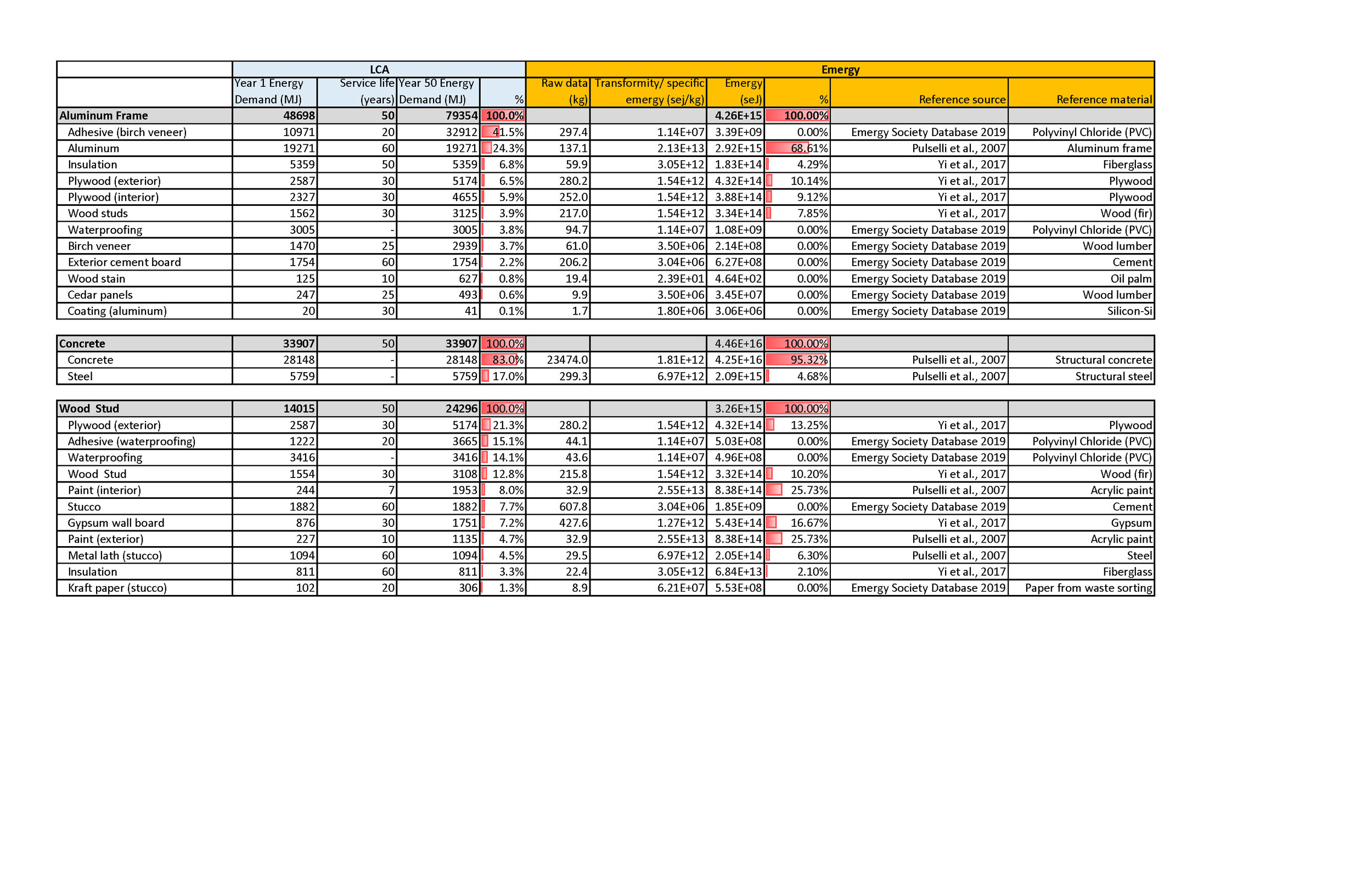

Tally also provided the necessary material data to run emergy analysis (spelled with an “m”). Emergy, a contraction of “energy” and “memory,” is a methodology rooted in thermodynamics and systems theory which measures the direct and indirect transformations of energy needed to make a product or service (Odum 1996, 370). Emergy provides a broader conceptual framework for understanding material and energy use in buildings as it accounts for natural resource production, unlike LCA methodologies which typically externalize these processes (Pulselli et al., 2007 and Yi et al., 2017). However, while emergy employs a broader scope, it is much less known in the building industry, meaning its databases contain less developed material and energy sources when compared to LCA. Emergy calculations were performed for the three facades to identify major differences from the LCA methodology. For more information on Tally’s LCA calculation methodology see Appendix 2.

OPERATIONAL ENERGY USE IN TWO CLIMATES

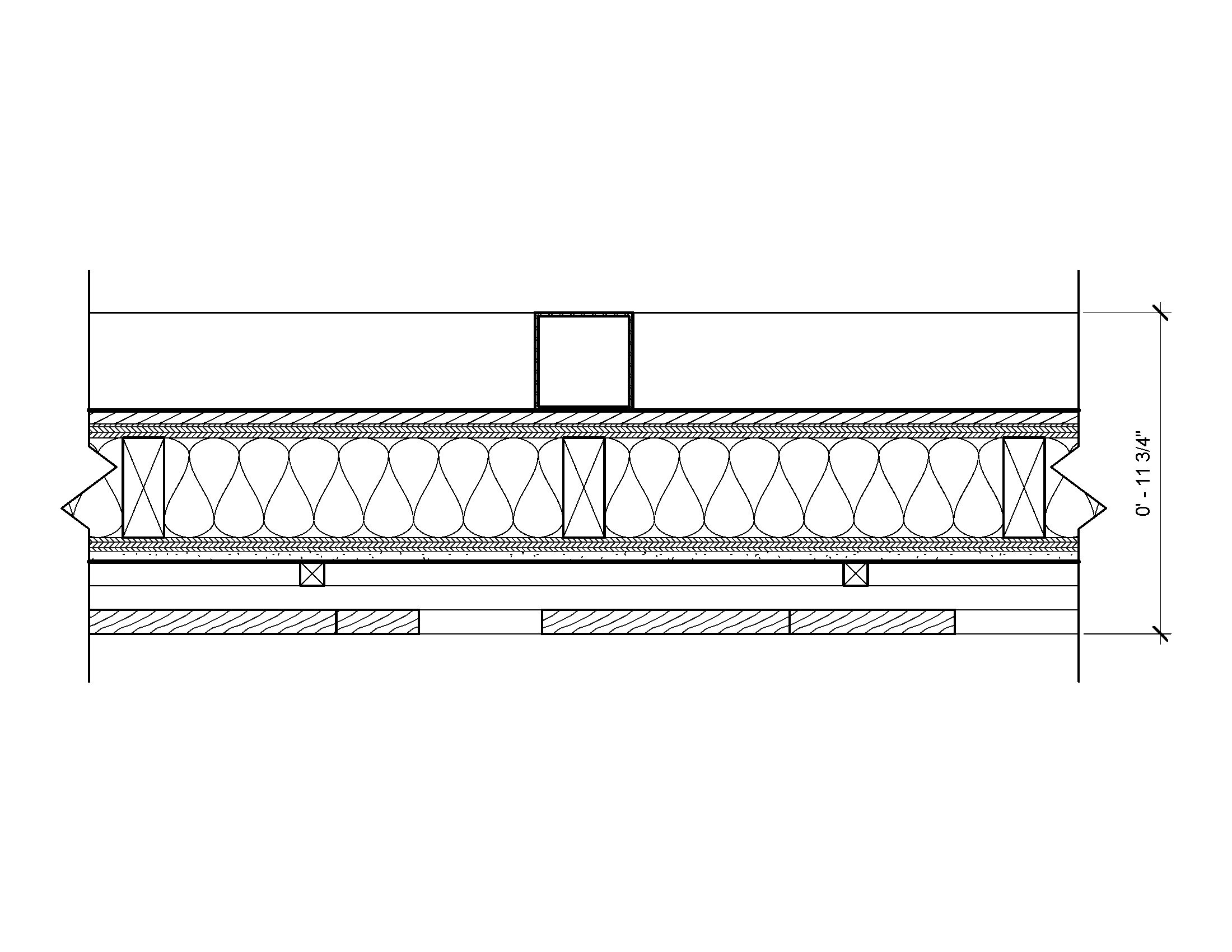

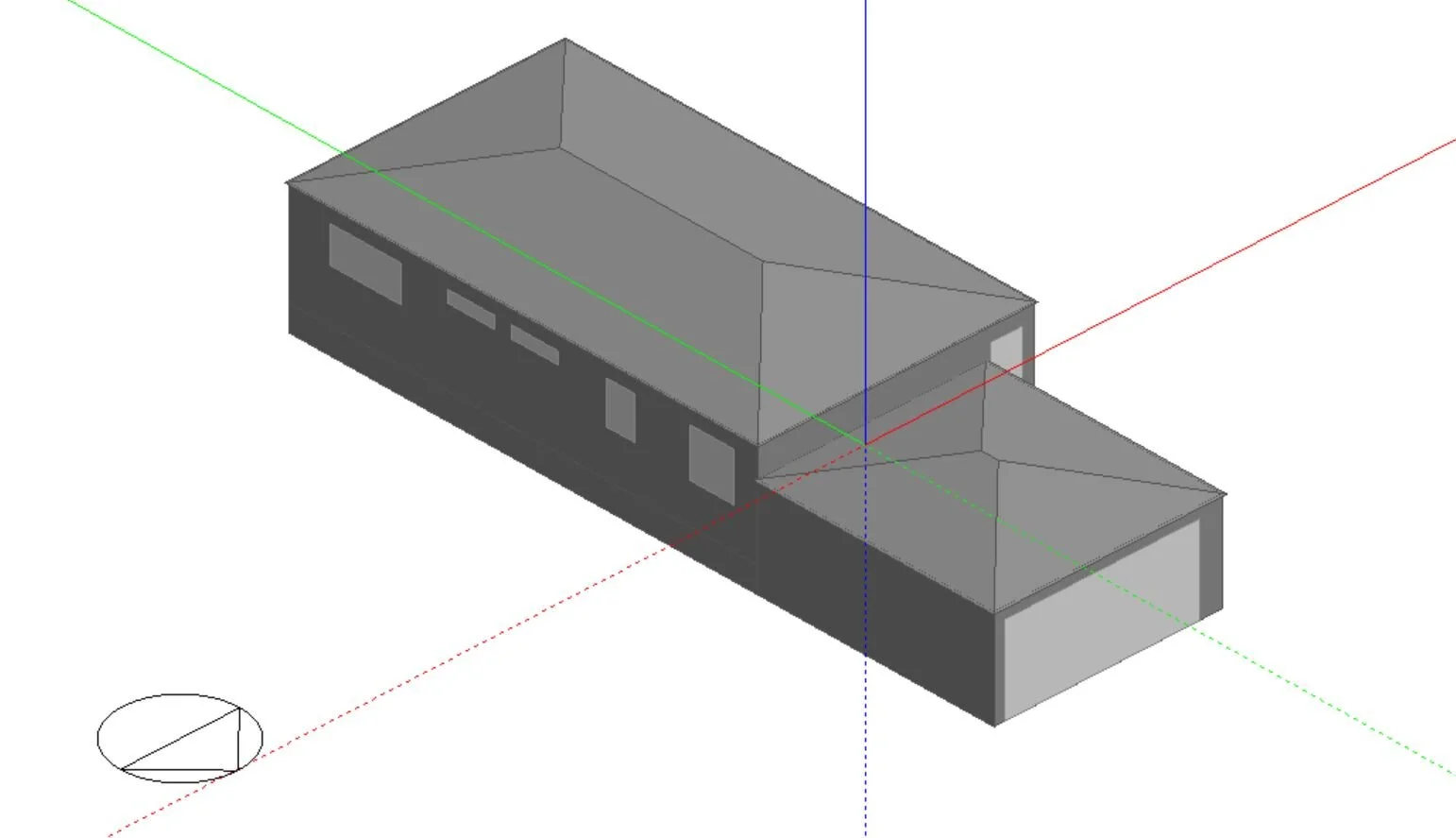

Since Tally does not provide operational energy use, the three assemblies were modeled as simple “shoebox” models– 26 ft x 26 ft x 10 ft rectangular geometries– and measured against a reference assembly in DesignBuilder, an EnergyPlus based software tool used to simulate energy, carbon, lighting, and comfort in buildings. The results from DesignBuilder were used as initial input values in Tally. The referenced assembly comprised of 5 inches of standard expanded polystyrene with a ½ inch wallboard panel on the interior surface for a total thermal resistance value of R-19 to match the other three assemblies. Adjacent exterior surfaces were defined as adiabatic denoting no heat transfer to allow for each facade assembly to be evaluated in isolation. All other variables remained constant and each assembly was simulated in two different climates (Los Angeles and Boston). The two buildings were also modeled in DesignBuilder using actual measurements taken of the Sehovic house. Appendix 3 shows the DesignBuilder setup of the facade and building models.

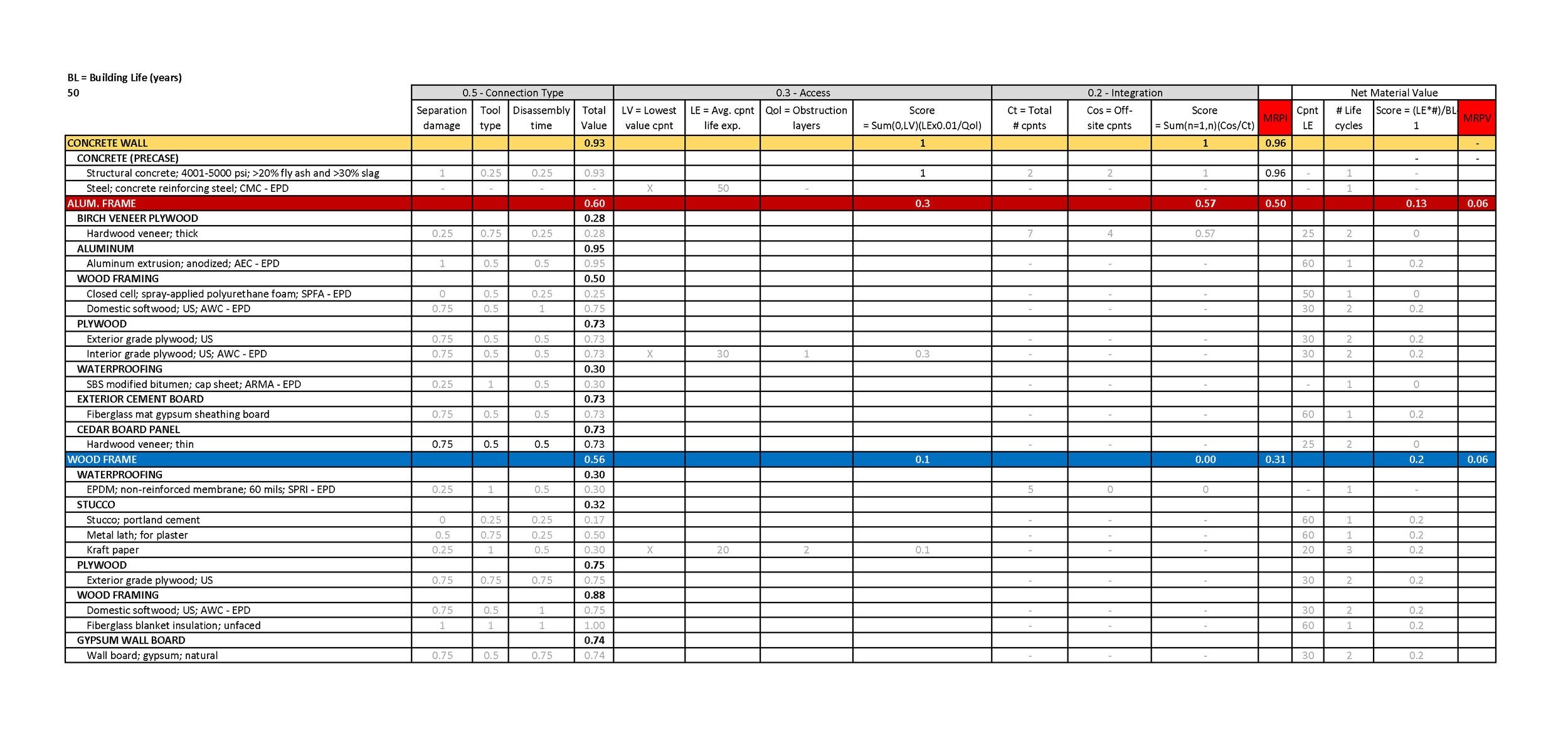

HIERARCHY OF MATERIAL RECOVERY POTENTIAL

While Tally includes end-of-life in its scope and an additional “Module D” showing the “benefits and loads beyond the system boundary from reuse, recycling, and energy recovery,” it only does so by using statistics of building products and not by taking assembly design into account. Therefore, an adapted version of the Material Recovery Potential Index (MRPI), a framework for evaluating circulatory assessment in building assemblies (Mayer and Bechthold 2017), served to provide material recovery potential indexes for the three assemblies using the following calculation:

Where: the Connection index contains values for separation damage, disassembly time, and tool type; Access considers the component with the lowest value in the assembly, its life expectancy, and the number of obstruction layers; and Integration considers the ratio between components preassembled offsite to total components in the assembly. (Note 8: See Mayer, M., & Bechthold, M. 2017. Development of policy metrics for circularity assessment in building assemblies. Economics and Policy of Energy and the Environment, 2017 (1), p.68 for MRP access and integration equations). While the MRPI assumes a weight for each of these indexes, it does not appear to weigh sub-variables such as separation damage, tool type, and disassembly time for connections. This inevitably penalizes heavier materials that might require larger machinery and more time to disassemble even though they possess greater strength and durability allowing higher potentials for reuse. For this reason, the adapted MRPI included sub-weights for the connection values as follows:

Where: SD represents separation damage; DT is disassembly time; and TT represents tool type (See Mayer and Bechthold 2017, p.66-67 for connection indexes). Separation damage carries a significantly higher score than disassembly time and tool type since materials with higher durability assume greater value than short-lived materials that can only be reused a limited number of times, if at all. Furthermore, since this analysis focused more on the configuration of different materials and assemblies, product scores were not considered in the adapted MRPI. The adapted MRPI therefore re-assigned the original 30% weight of the product score equally to connection, access, and integration to get the new weights as per Equation 1 above (See ibid, p.71 for original MRPI assembly module weights). Sub-weights for access and integration were not assigned as they are largely influenced by connection type. Lastly, while the MRPI measures the quantity of recovered material, it does not measure material quality or value. This study provides an additional metric to account for material quality called the Material Recovery Potential Value (MRPV):

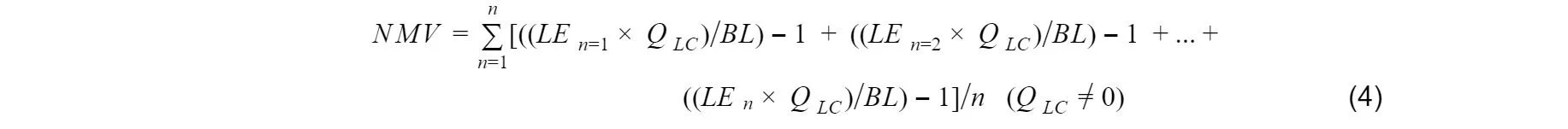

Where: the MRPV is calculated using the adapted MRPI and the Net Material Value (NMV):

Where: n is the nth component in the assembly; LE is the life expectancy of the component; QLC represents the number of component life cycles or replacement times in the building lifetime; and BL is the building lifetime. A higher score represents a more durable, and therefore, more valuable building material since it is more likely to be reused. For example, a score of 0.2 suggests a recovered material with the potential to serve 20% of the previous building’s lifetime in a new building since it possesses lower durability. Conversely, a score of 2.0 suggests a material has the potential to serve twice the lifetime of the previous building in a future building. The higher the score, the more durable and useful the material. Materials such as concrete and steel theoretically have unlimited lifetimes, and thus indefinite values, assuming they contain no structural damage, are adequately maintained and can be reused. It should be noted here that the service life of concrete and steel are automatically set to the lifetime of the building in Tally precisely because of their superior durabilities.

Using the methodology described above, the three facades and two buildings were analyzed based on their material embodied energy, operational energy use, and material recovery potential.

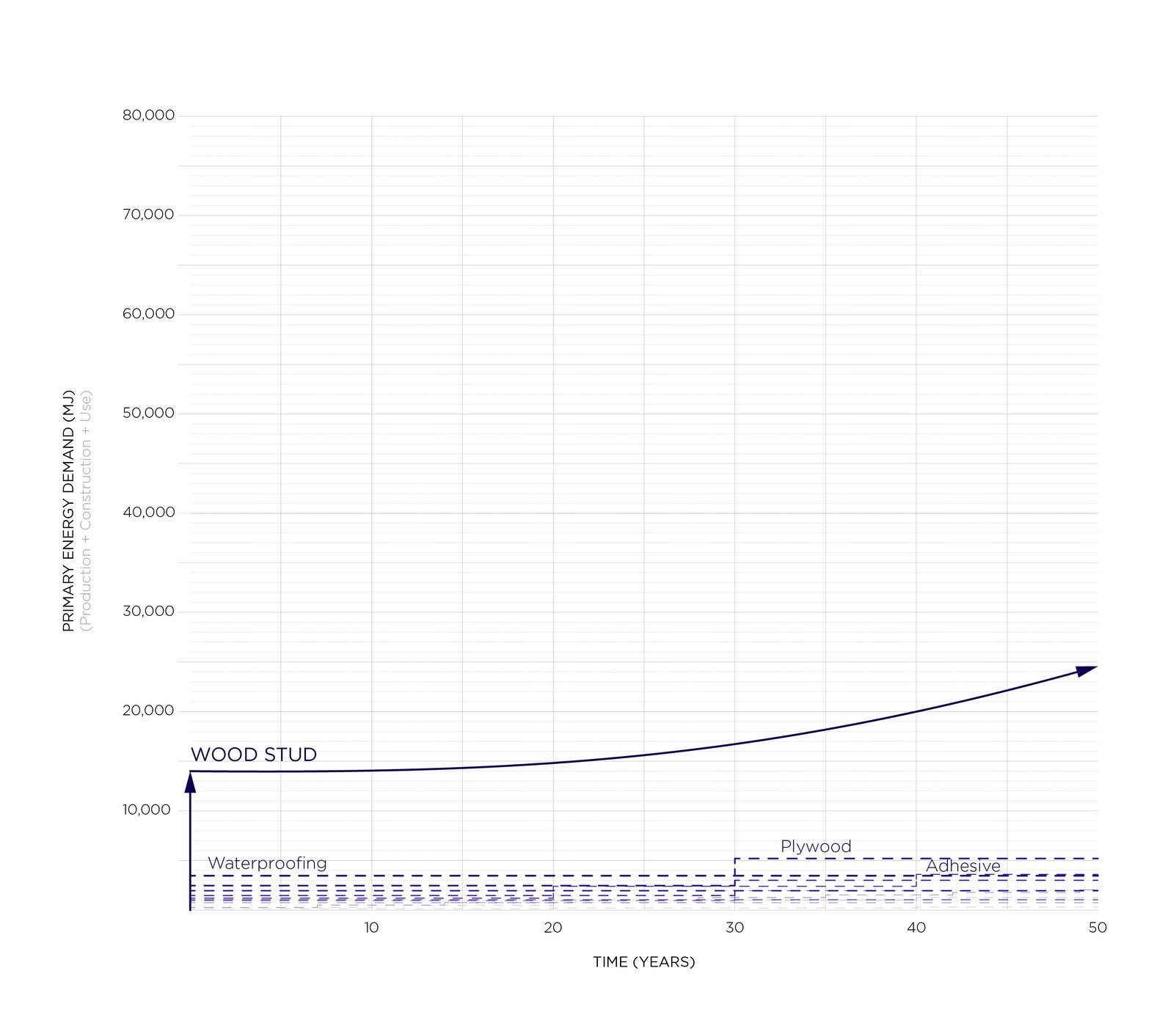

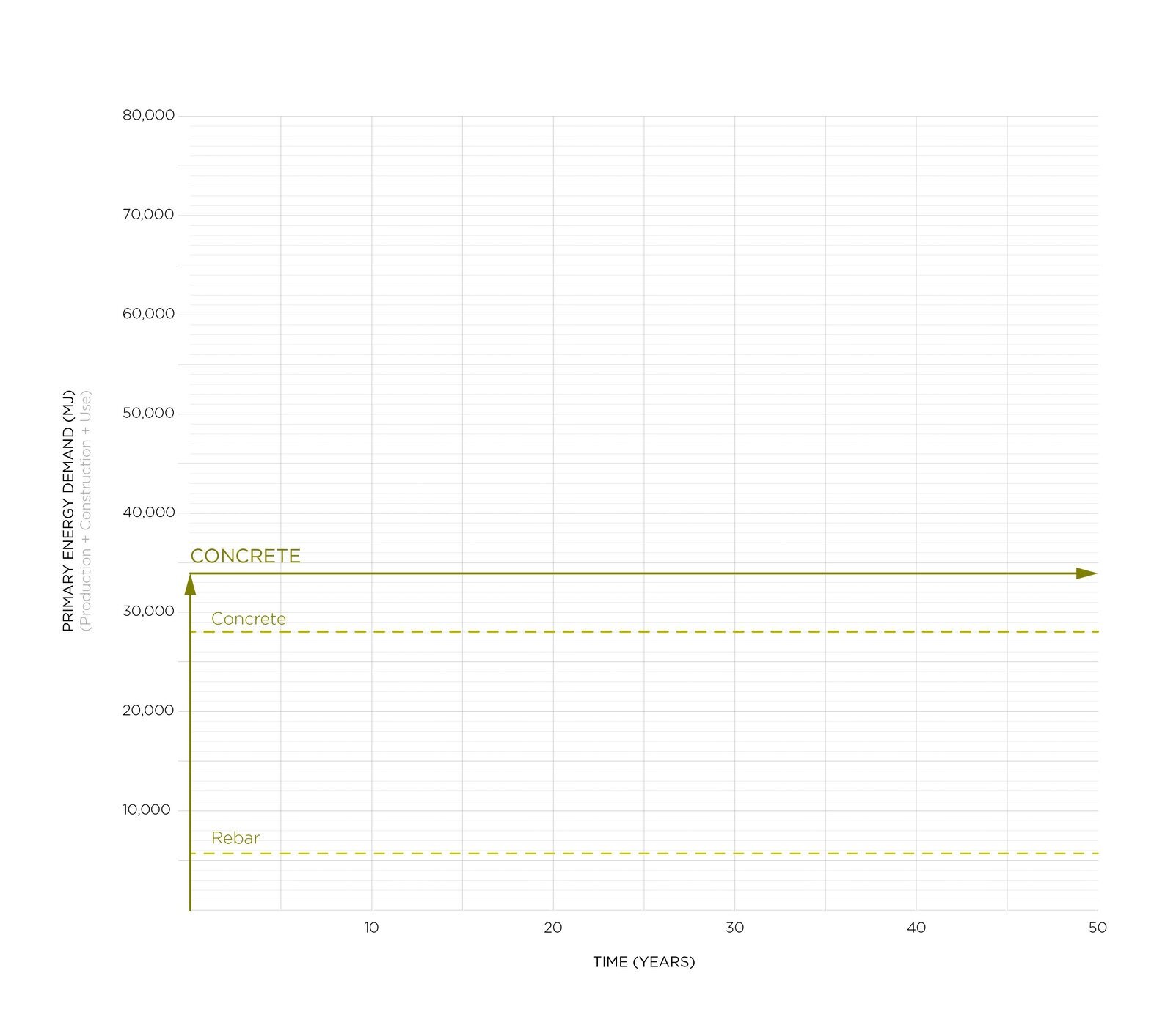

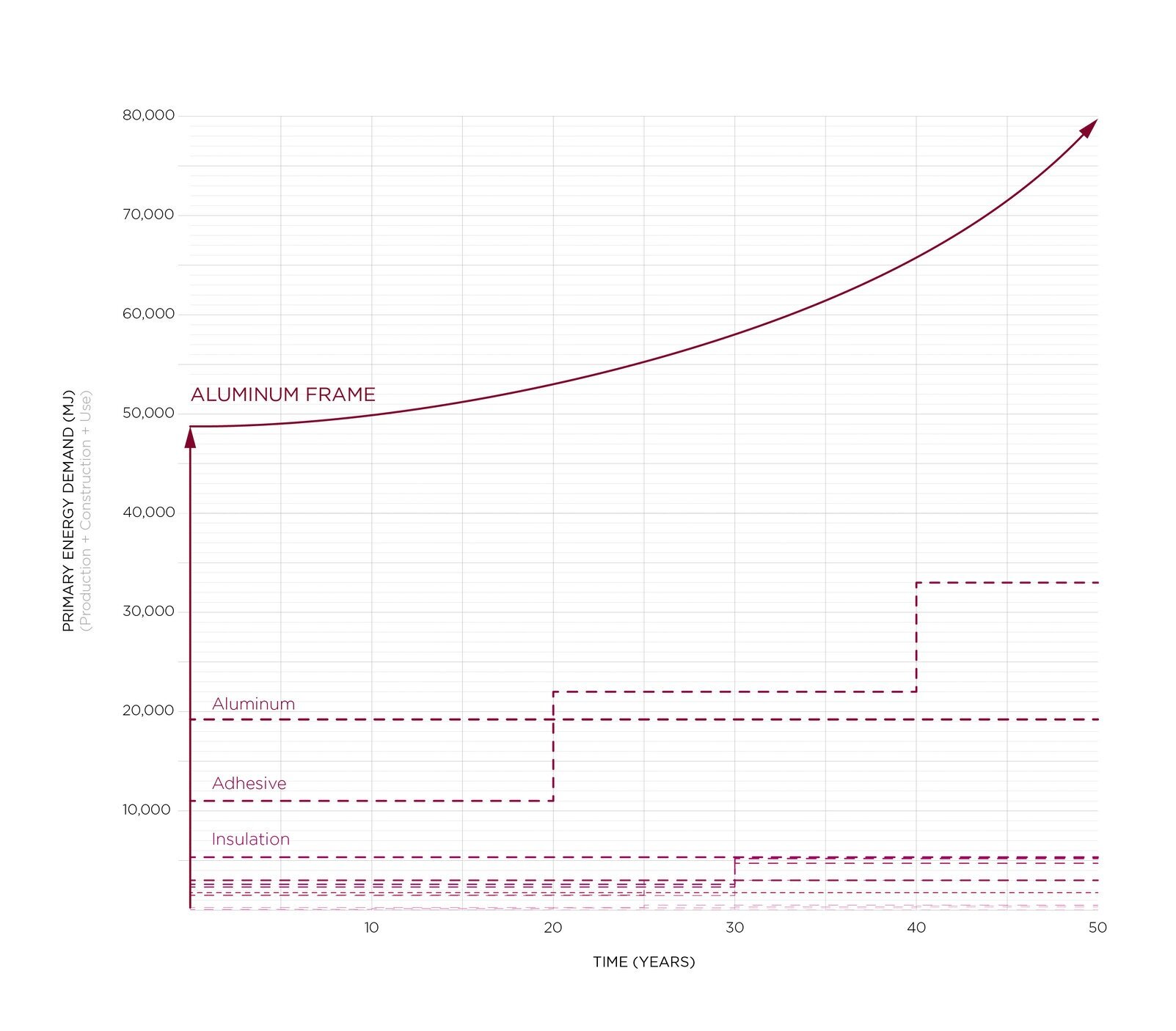

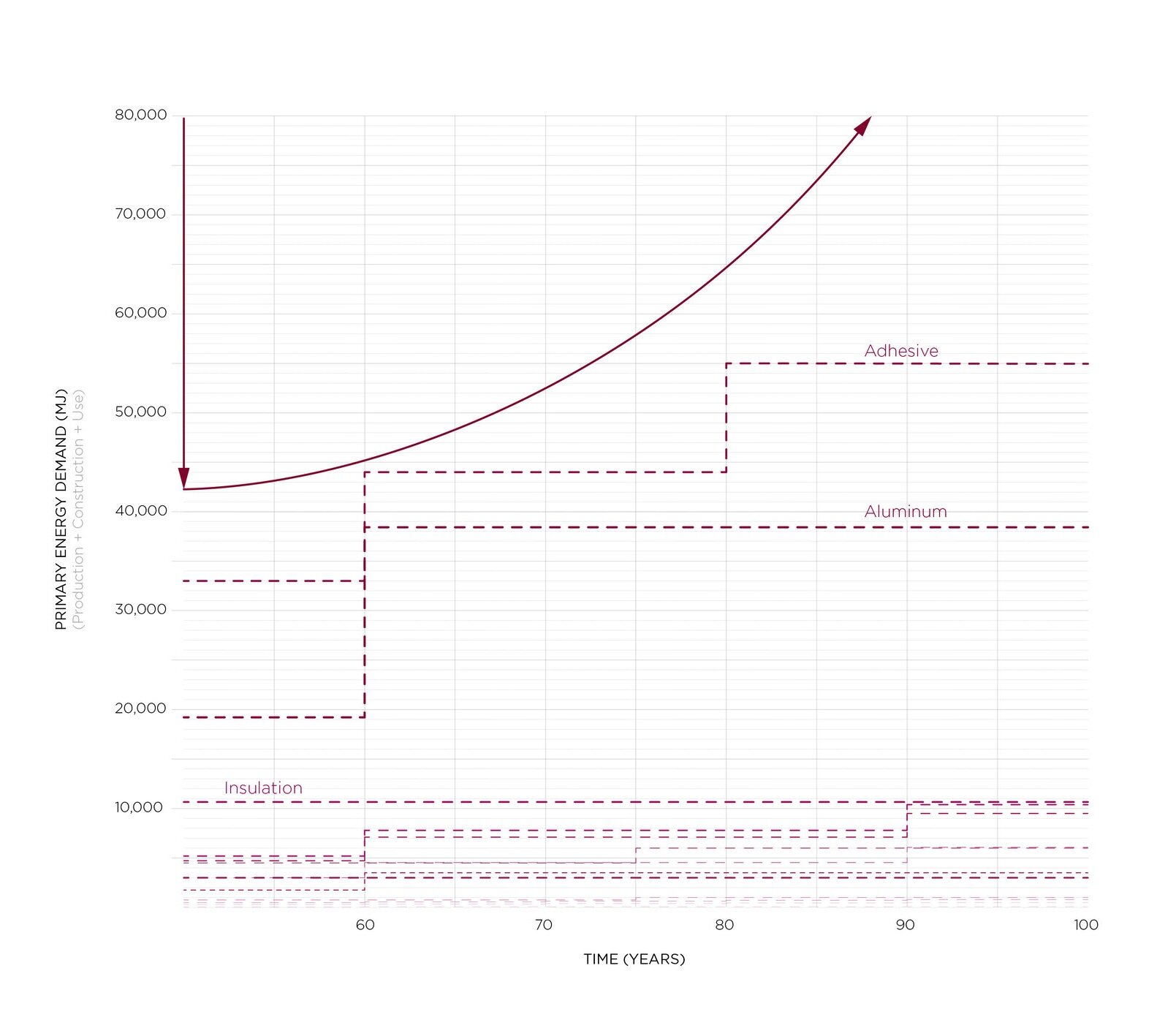

Facade Material Embodied Energy

The embodied energy of materials for the three facades was tested for a typical 50-year building lifetime shown in the graphs above. The energy demand for the wood stud and aluminum frame assemblies gradually increased from 14,015 MJ to 24,296 MJ and from 48,698 MJ to 79,354 MJ due to maintenance and replacement while the more durable concrete assembly remained constant at 33,907 MJ over the 50-year period. The increases in energy demand for the wood and aluminum assemblies was primarily associated to the exterior plywood and polyurethane adhesive needing to be replaced multiple times over the building’s lifetime due to their shorter lifespans (30 and 20 years, respectively). A comparison of the LCA and emergy methodology was also performed for the three facade assemblies which can be found in Appendix 4. The initial results seem to indicate that emergy weighs the energy required to produce raw materials such as wood and aluminum more heavily than LCA which places more emphasis on the energy required to produce synthetic materials that have chemicals such as polyvinyl chloride used in building adhesives, for example. From a theoretical point of view, this agrees with emergy’s broader approach of accounting for the energy required in natural resource production.

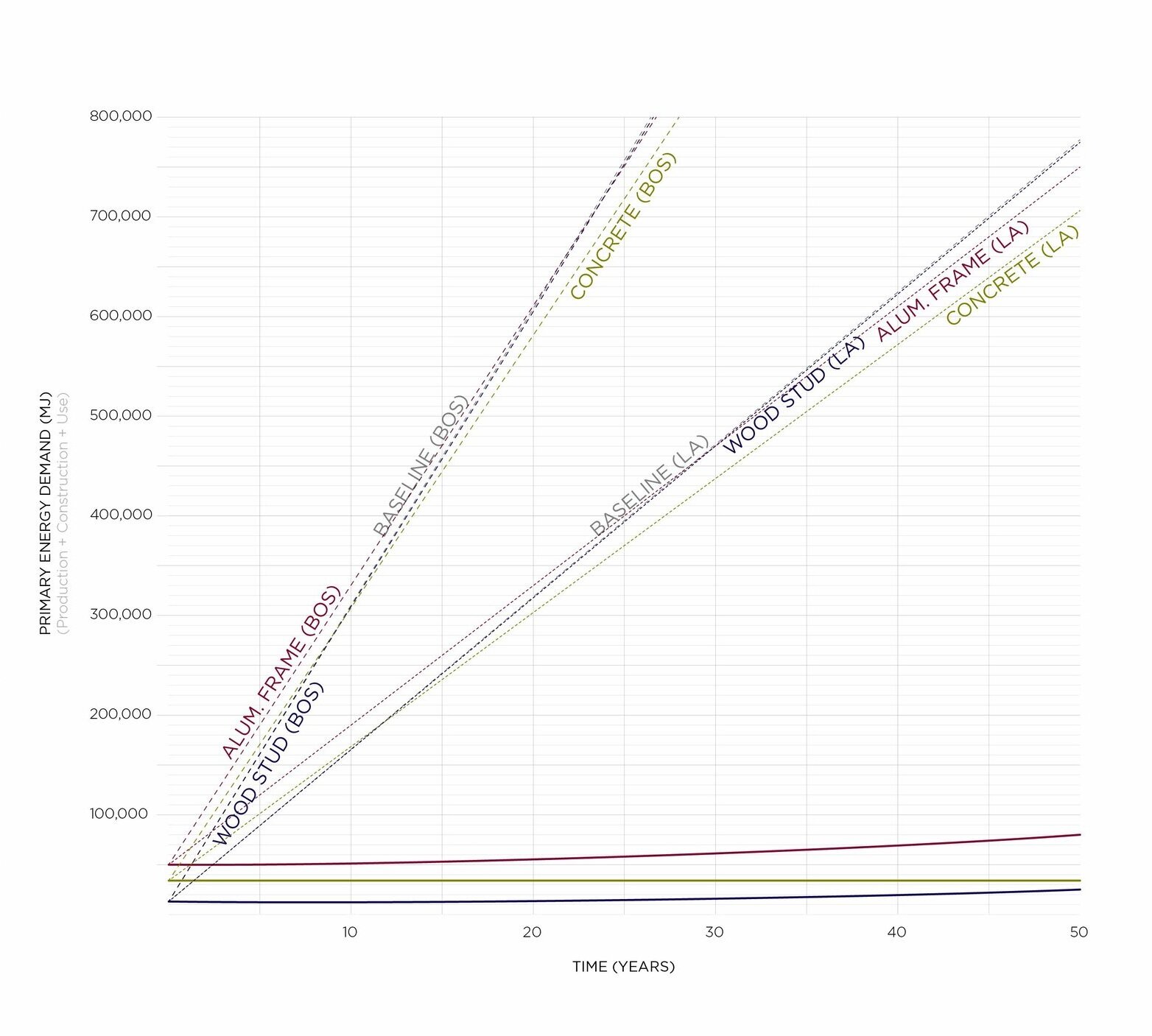

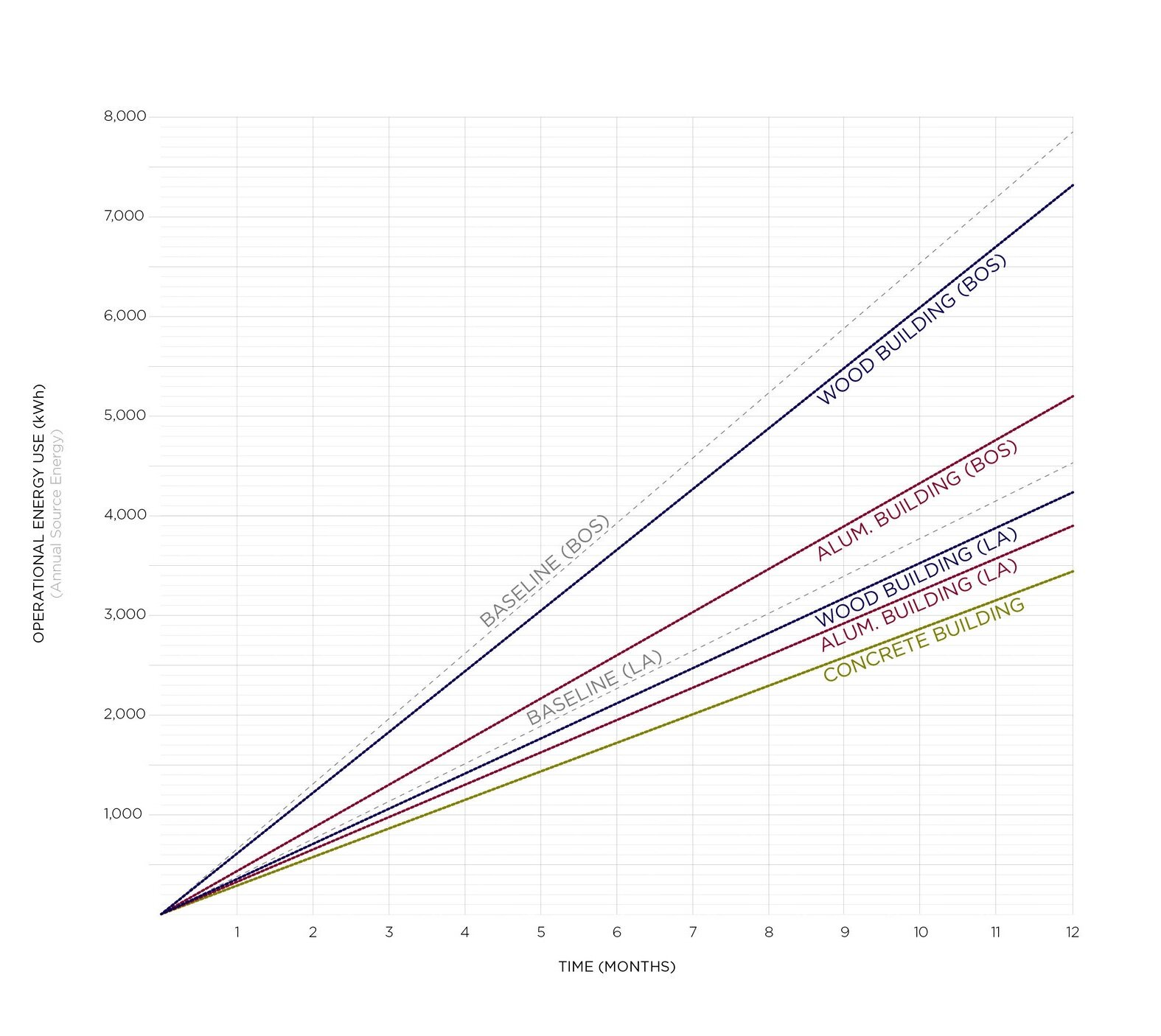

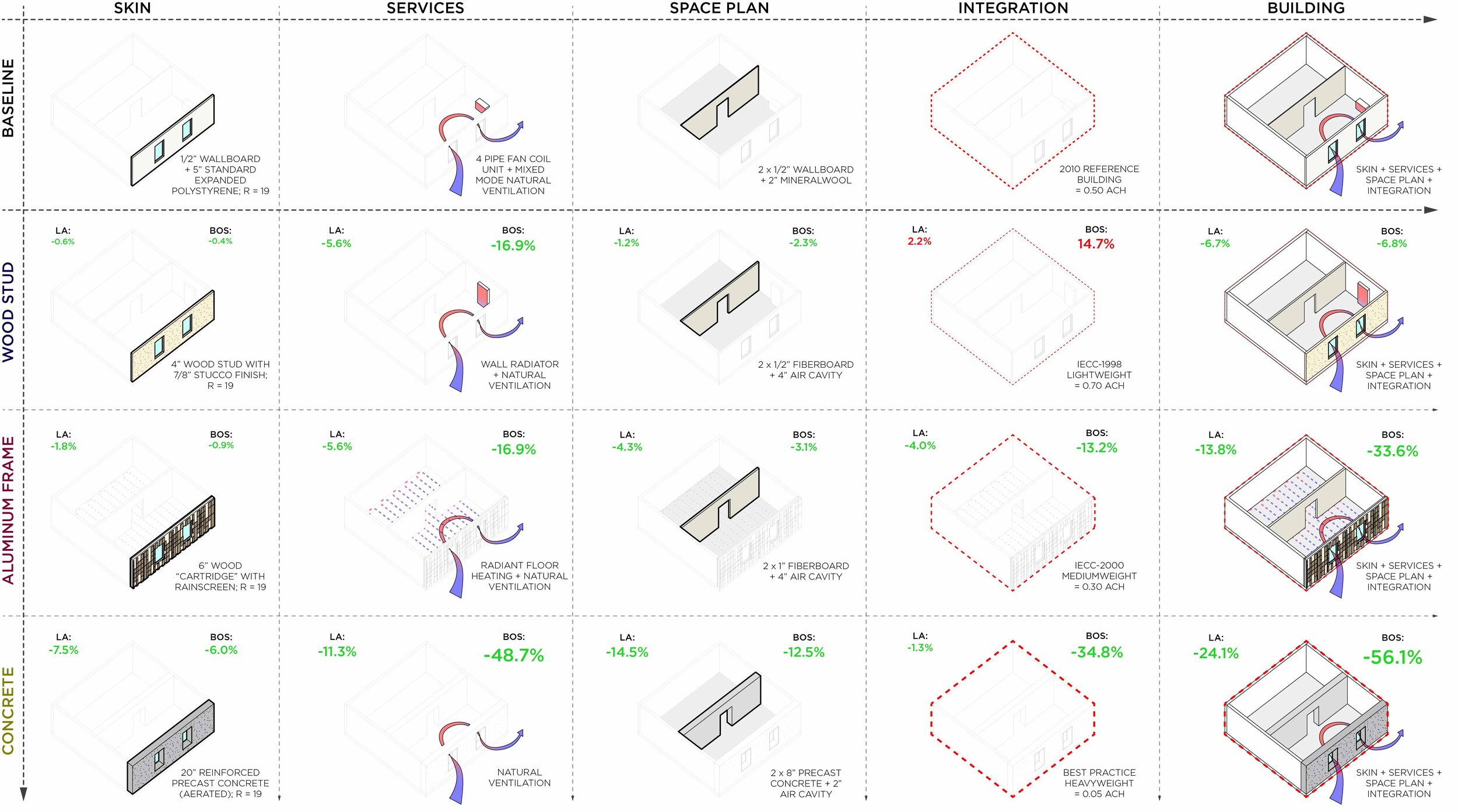

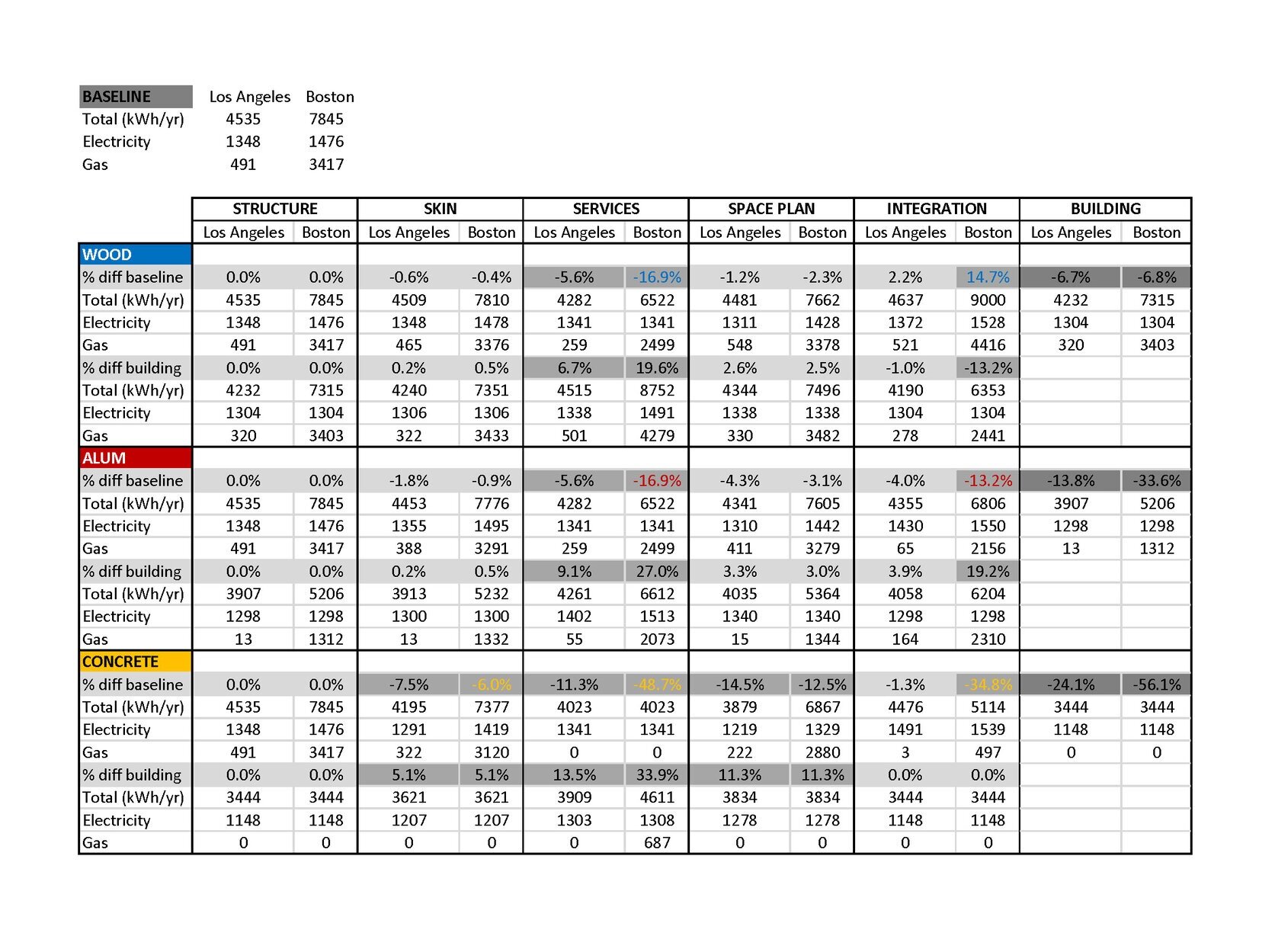

Facade Operational Energy Use

While all three models exhibited nearly twice the operational energy use in Boston than in Los Angeles mainly due to increased heating demands, the concrete facade performed better than the other two assemblies in both climates when compared to the expanded polystyrene reference assembly which served as a baseline for the comparison in the figure above. The concrete facade’s ability to provide radiant heating and cooling with thermal mass reduced energy demand by 7.5% and 6.0% in Los Angeles and Boston compared to reductions of 1.8% and 0.9% for the aluminum facade and 0.6% and 0.4% for the wood facade from the baseline. See Appendix 5 for a diagram of the simulation inputs and operational energy impacts for each facade (skin) shoebox building.

Facade Material Recovery Potential

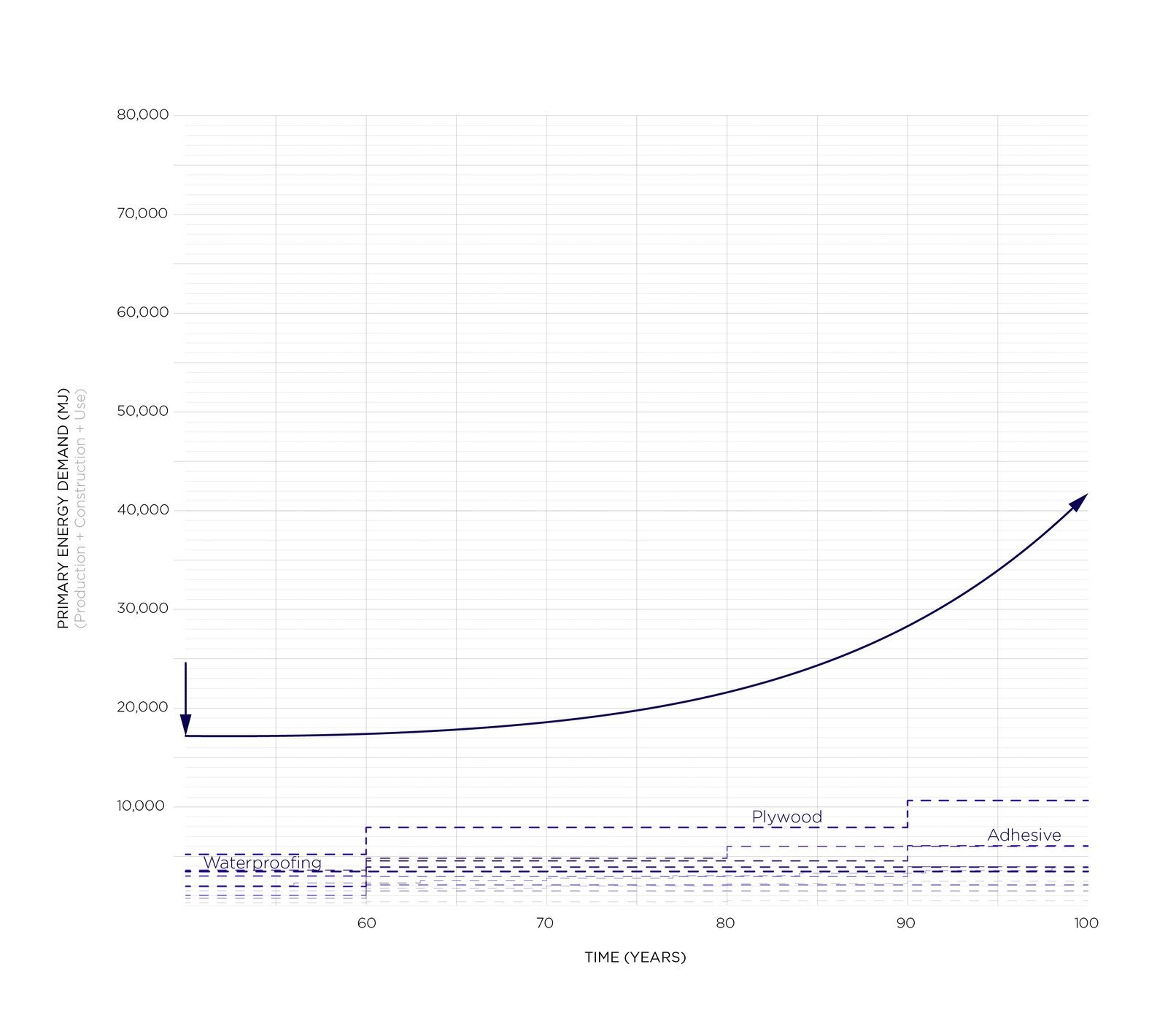

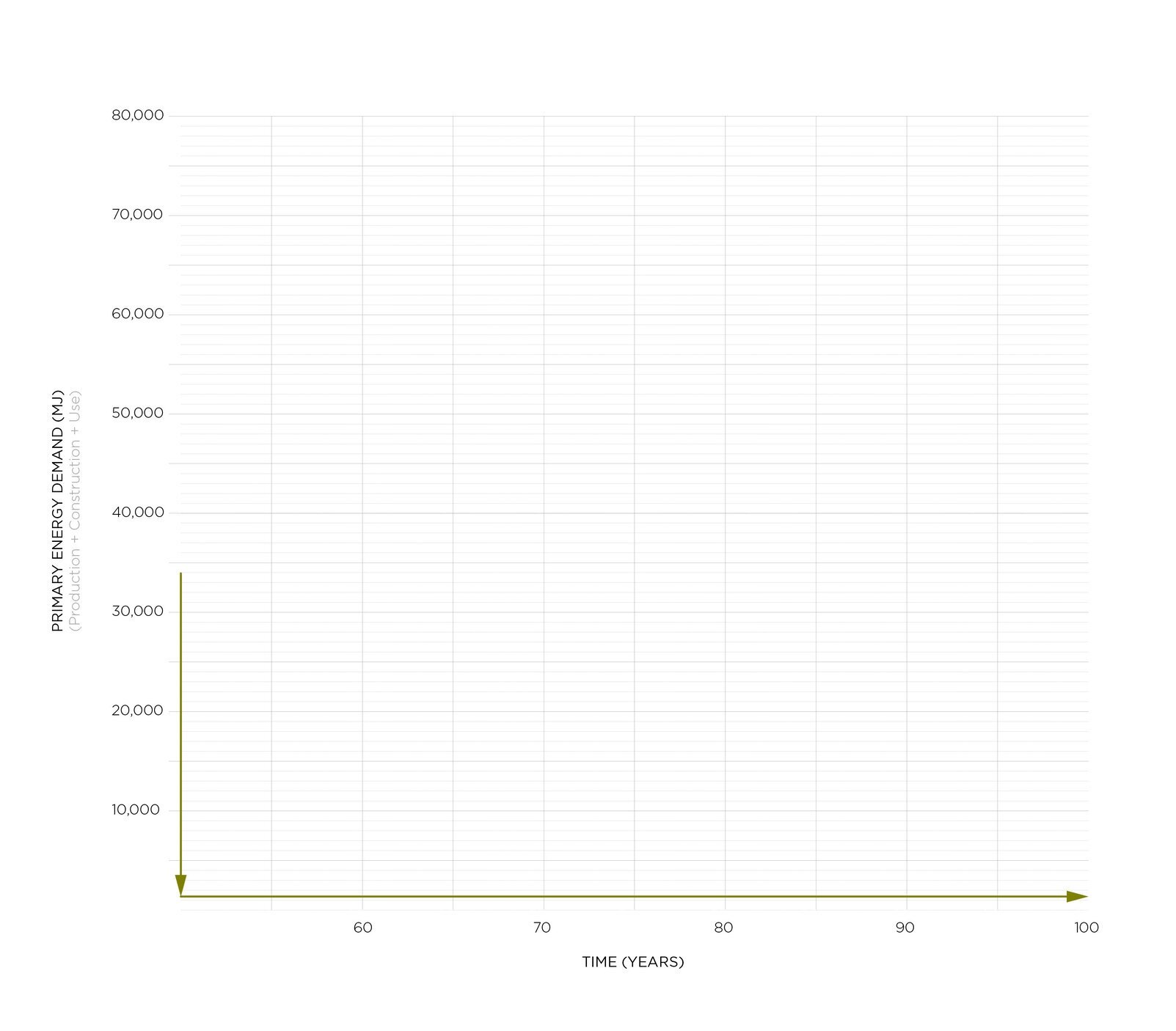

The adapted MRPI and MRPV provided material recovery potentials for the three facade assemblies. In addition to receiving MRPI scores of 0.31 and 0.50– mainly due to their limited connections, access, and integration– the wood and aluminum assemblies received significantly lower MRPV scores (0.06 for both) since they contain more short-lived materials. Conversely, the concrete assembly received a MRPI score of 0.96 and, by default, an “indefinite” score for MRPV since it theoretically has the potential to be reused indefinitely due to its superior durability. The figures represent the recovery potential of the three assemblies (wood, concrete, aluminum) while hypothetically extending the building lifespan to 100 years to demonstrate the effects of short-lived materials on the MRPV score. Appendix 6 contains the score breakdowns for each facade assembly.

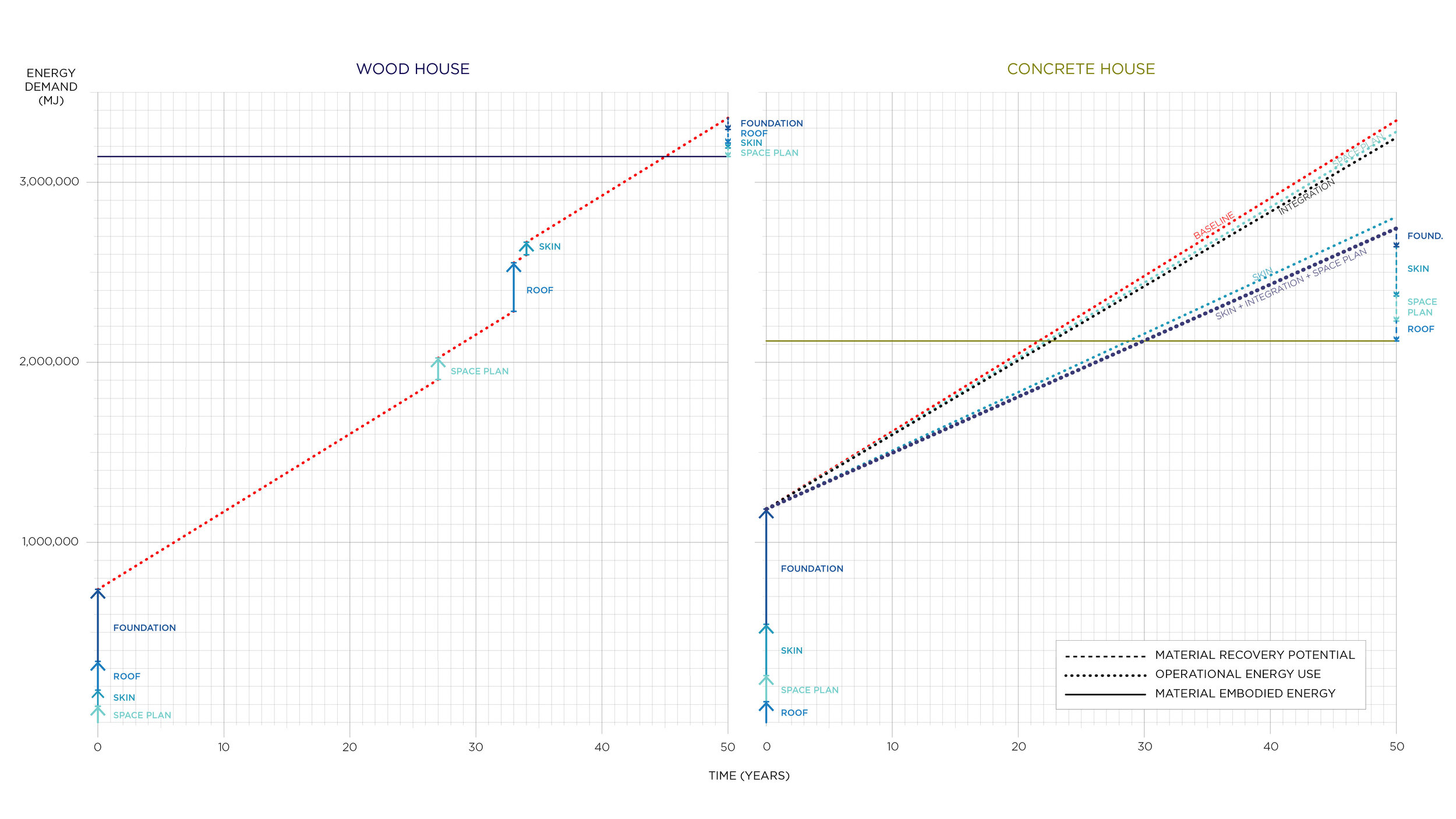

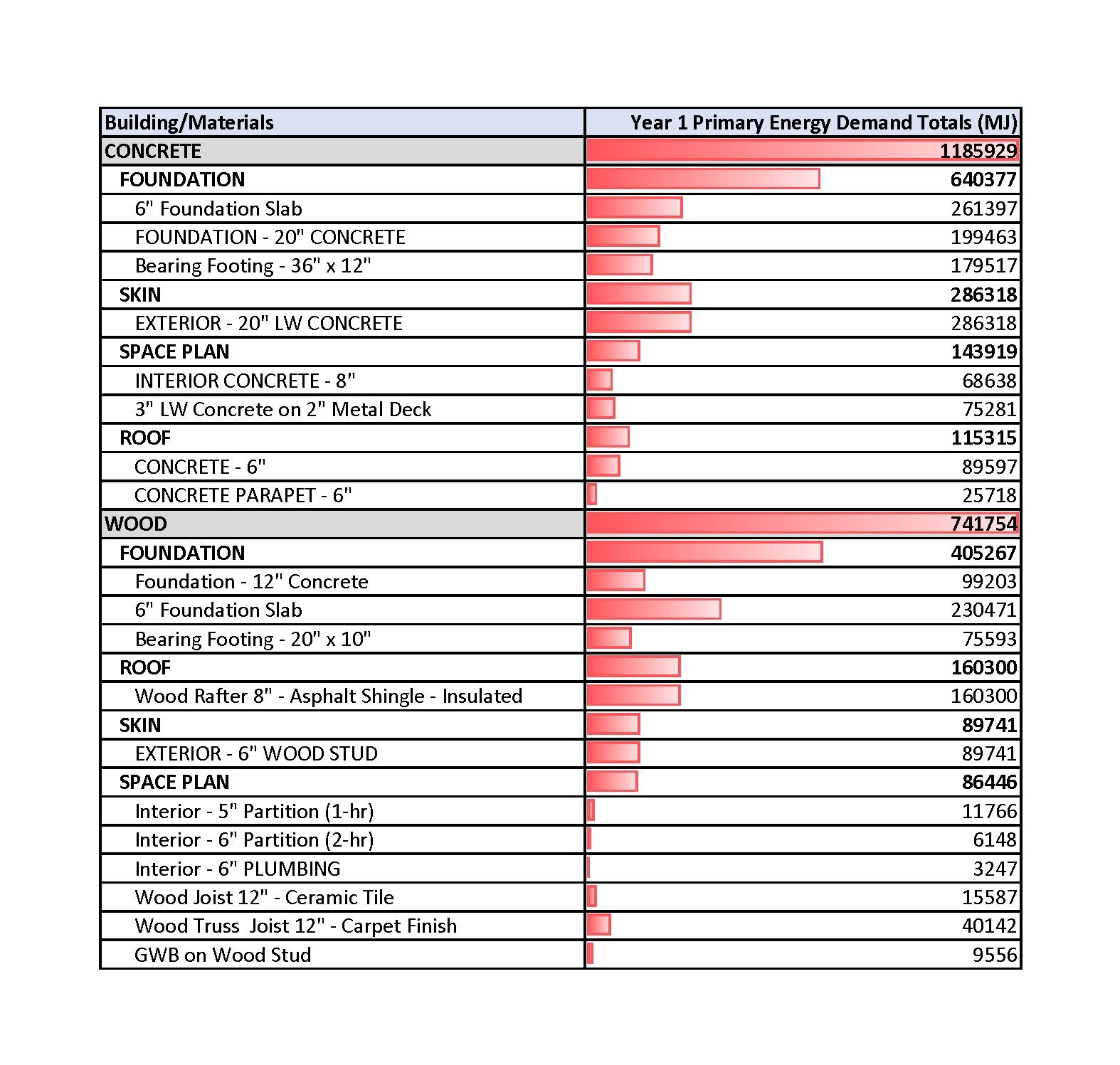

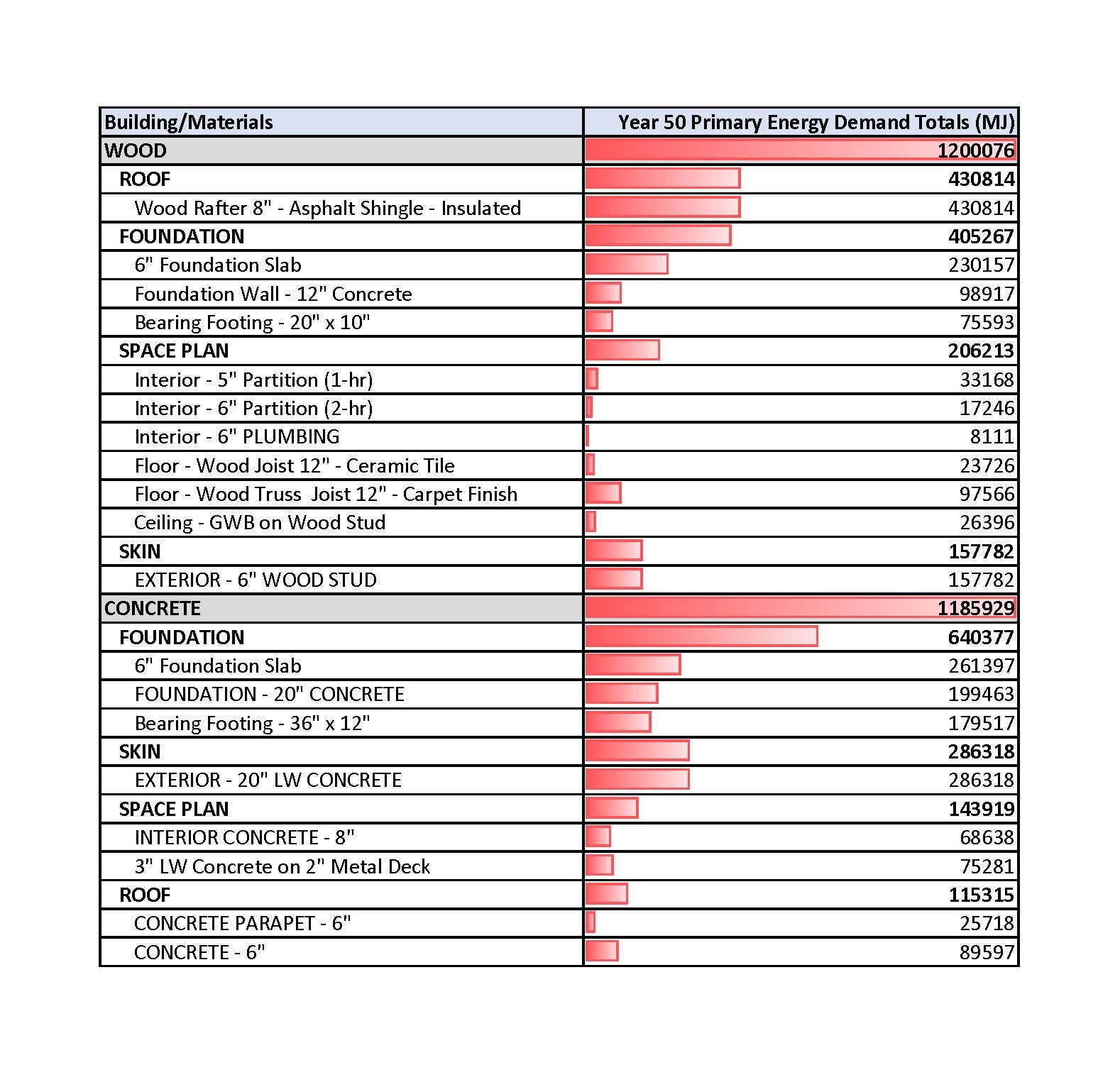

House Material Embodied Energy

The Sehovic house in wood and concrete followed similar patterns in terms of material embodied energy as the wood and concrete facades illustrated above. The wood house gradually increased from 741,754 MJ to 1,200,076 MJ while the concrete house stayed constant at 1,185,929 MJ over the 50-year period. Embodied energy for the roof and space plan represented the most significant increases in the wood house by more than doubling from 160,300 MJ to 430,814 MJ and from 86,446 MJ to 206,213 MJ, respectively. This was mostly due to the high energy intensity of the asphalt shingles and carpet flooring which have typical lifespans of only 20 and 10 years. In other words, the wood building exhibited significantly higher increases in embodied energy over its lifetime specifically because of its design and construction logic which utilizes multiple assembly layers of low durability materials. For a detailed breakdown of the embodied energy intensity for each building element see Appendix 7.

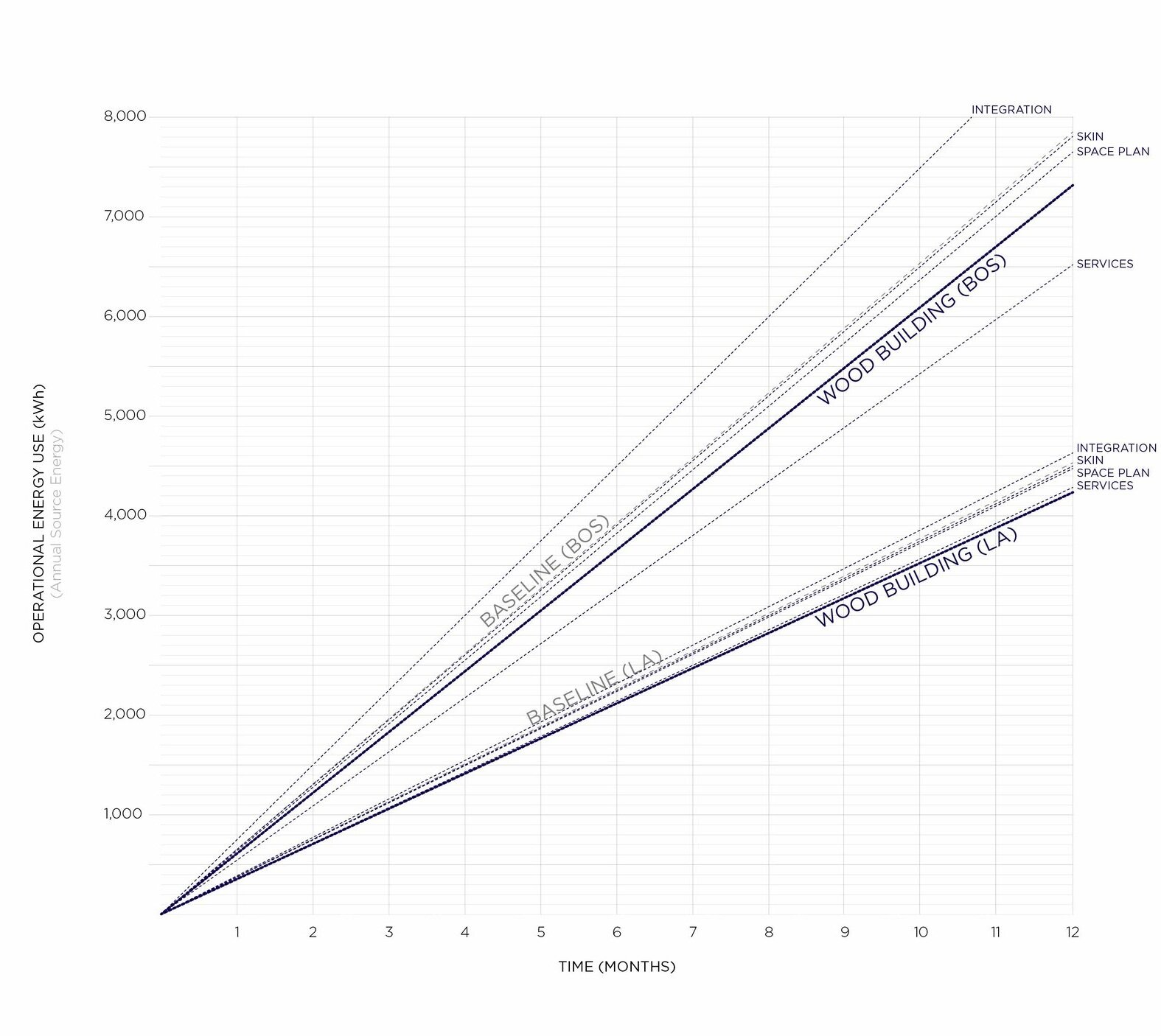

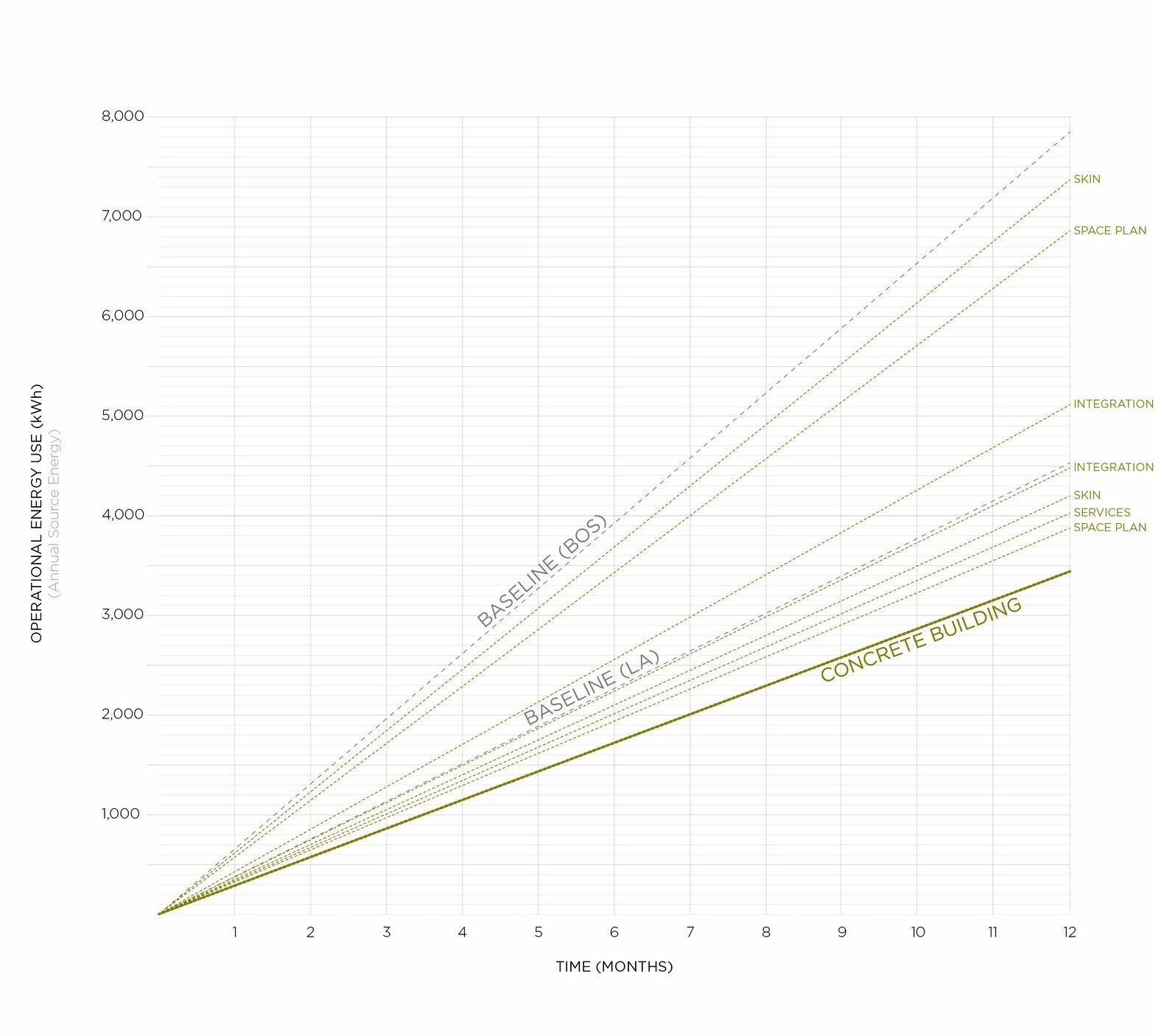

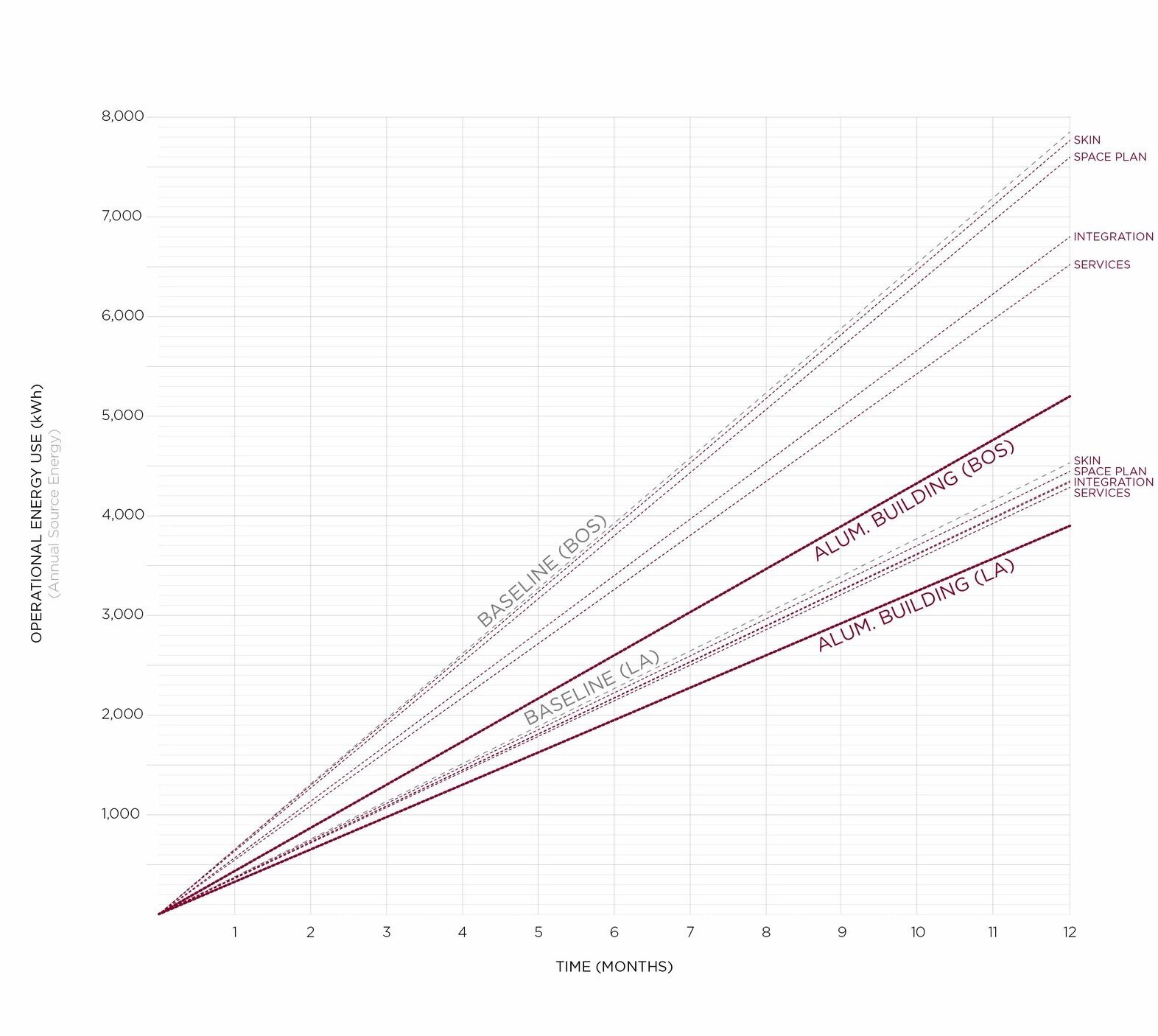

Building "Shoebox" Operational Energy Use

The boundary of the original facade shoebox models was expanded to test other building elements and factors such as space plan, services, and integration before evaluating the Sehovic house. Although services were considered negligible in the material embodied energy calculations, they exhibited significant impacts on operational energy use; therefore they were accounted for here. An integration factor was introduced to account for the way building systems come together in practice. This was measured by the number of air changes per hour (ACH) to represent the quality between on-site and off-site construction techniques. Off-site or factory-built construction typically produces less leaky buildings which have lower ACH values. The results demonstrated that services, space plan, and integration could have significant impacts on operational energy use in all three shoebox buildings. However, this was mostly dependent on the climate and the type of building materials used. Services and integration displayed much higher energy differences between the Los Angeles and Boston climate compared to the space plan, for example. The concrete shoebox building performed nearly twice as better than the aluminum frame building which performed about twice as better than the wood building in both climates shown above. For more information on the simulation inputs and a detailed breakdown of each shoebox building element’s energy performance see Appendix 5.

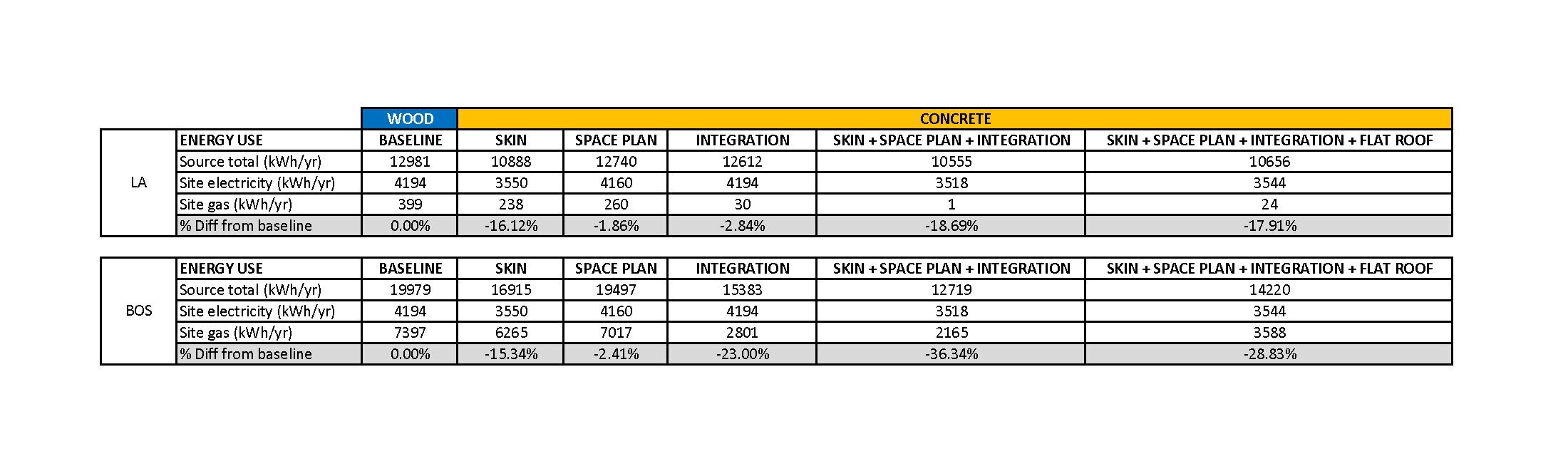

House Operational Energy Use

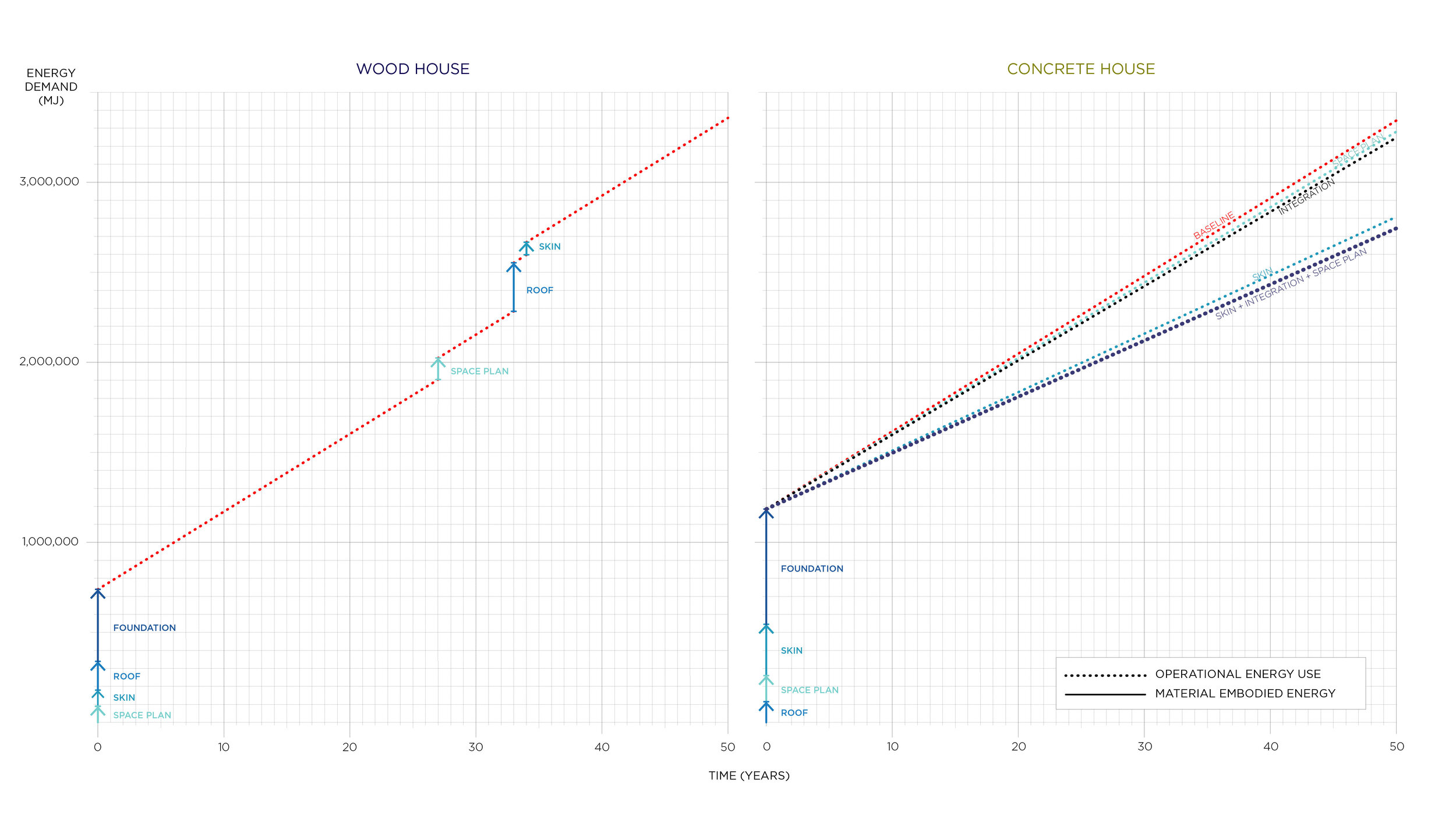

Transferring the methodology to the Sehovic house, results revealed significantly higher energy reductions due to the concrete skin at the building level than at the facade level in both Los Angeles and Boston (16.1% and 15.3%, respectively). This is likely because the skin in the house accounts for more surface area than in the shoebox models. The space plan demonstrated much less of an impact in the two climates with reductions of only 1.6% and 2.1% in energy use. Integration revealed a much higher sensitivity to climate with energy reductions of only 2.8% in Los Angeles but 23.0% in Boston. When combined– the skin, space plan, and building integration– provided overall energy reductions of 18.7% and 36.4% in the two climates. A more appropriate roof and floor system for the concrete house was modeled decreasing the energy performances to 17.9% and 28.8% in the two climates. This was mainly due to slight increases in building volume with the higher roof height in the garage space in the concrete house. Essentially, the concrete skin yielded significantly higher energy savings than the other building systems; this makes sense considering a building’s skin is its first and main line of defense from the exterior environment. The graphs above illustrate the operational energy performance for the two houses in Los Angeles in relation to their embodied energy over the 50 year lifespan. For a more detailed breakdown of operational energy use for the two houses in both climates see Appendix 8.

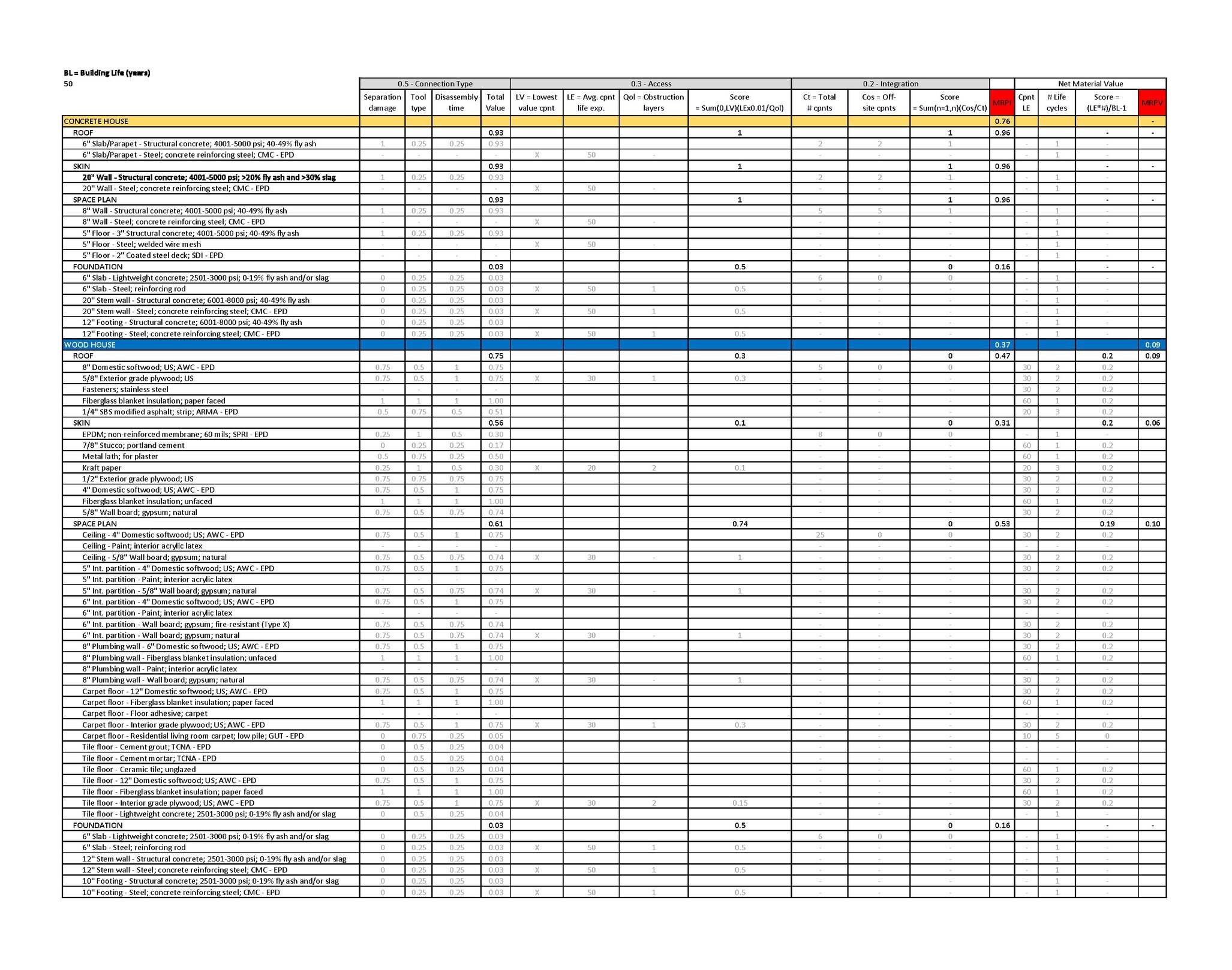

House Material Recovery Potential

In terms of material recovery potential at each building’s end-of-life, the concrete and wood houses received scores of 0.76 and 0.37 for MRPI and MRPV scores of “indefinite” and 0.09, respectively. While the roof, skin, and space plan in the concrete building all received MRPI values of 0.96 because of their superior connections, access, and integration, the site-built foundation in both buildings only received a MRPI value of 0.16 because of its cast-in-place connections lowering the overall MRPI score for both buildings. The roof, skin, and space plan in the wood house received individual values of 0.47, 0.31, and 0.53 for MRPI and 0.09, 0.06, 0.10 for MRPV due to their short-lived materials. In other words, the wood building yielded significantly lower material recovery scores because it employs multiple layers of poorly integrated and low durable materials that were all built on-site. The graphs above show the material recovery potential of the wood and concrete house at year 50 in relation to operational energy use and overall embodied energy for comparison. For a detailed breakdown of the MRPI and MRPV scores see Appendix 9.

DISCUSSION

This thesis reveals links between material embodied energy, operational energy use, and material recovery potential in building assemblies. It demonstrates opportunities to improve the way buildings use material and energy by designing monolithic assemblies with high thermal mass materials. Although this study only examined concrete as a high thermal mass material, the results reveal that these types of materials could offer significantly higher reductions in energy demands on maintenance, replacement, repair, and ultimately on a building’s overall embodied energy. Moreover, these materials’ capacity for thermal storage also improves operational energy performance and comfort for building occupants. Perhaps more importantly, they are easier to design and build given their reduced number of assembly layers which improves building connections, access, and integration enabling significantly greater opportunities to recover and potentially reuse valuable materials at the end of a building’s lifetime. While the work presented here shows a typical 50-year building lifetime, experiments were also extended to include 100 and 200-year lifetimes which demonstrate not only the superior durability of these assemblies but also the benefits of amortizing their energy reductions over longer periods of time. It should also be highlighted here that although environmental impacts associated with global warming from CO2 emissions were not a focus of this thesis, a significant portion of those emissions comes directly from building energy use and material production for construction activities. Moreover, as the recovery and reuse of materials such as concrete and steel increases, the large amount of CO2 emissions released during their production will decrease. Ultimately, the findings from this thesis seem to indicate alternative ways to conceptualize and design buildings while offering new possibilities for the practice of architecture that reduce material waste, improve resource productivity, and empower architects to have a greater impact on large-scale social and ecological concerns.

Pulsing Building Systems

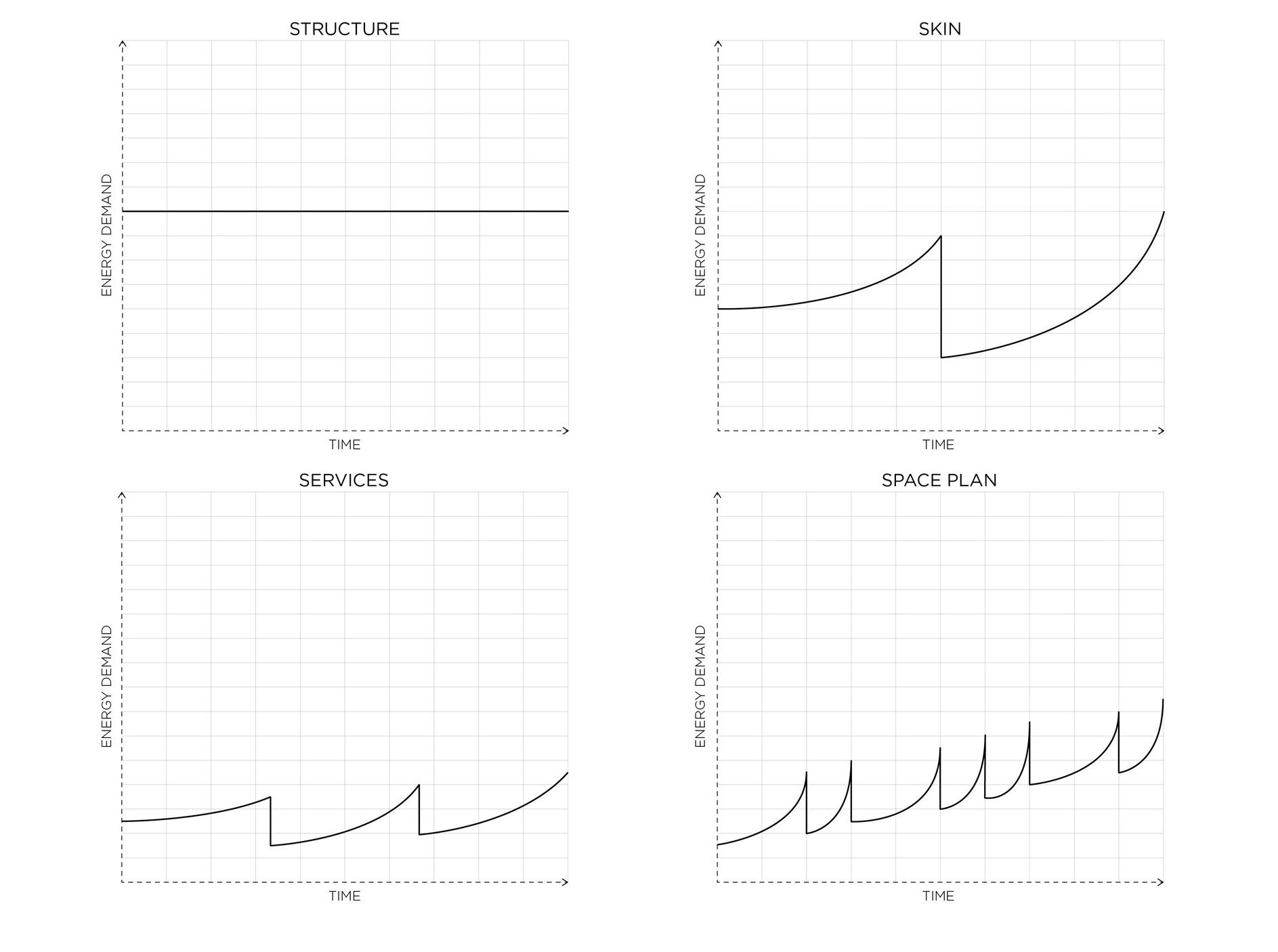

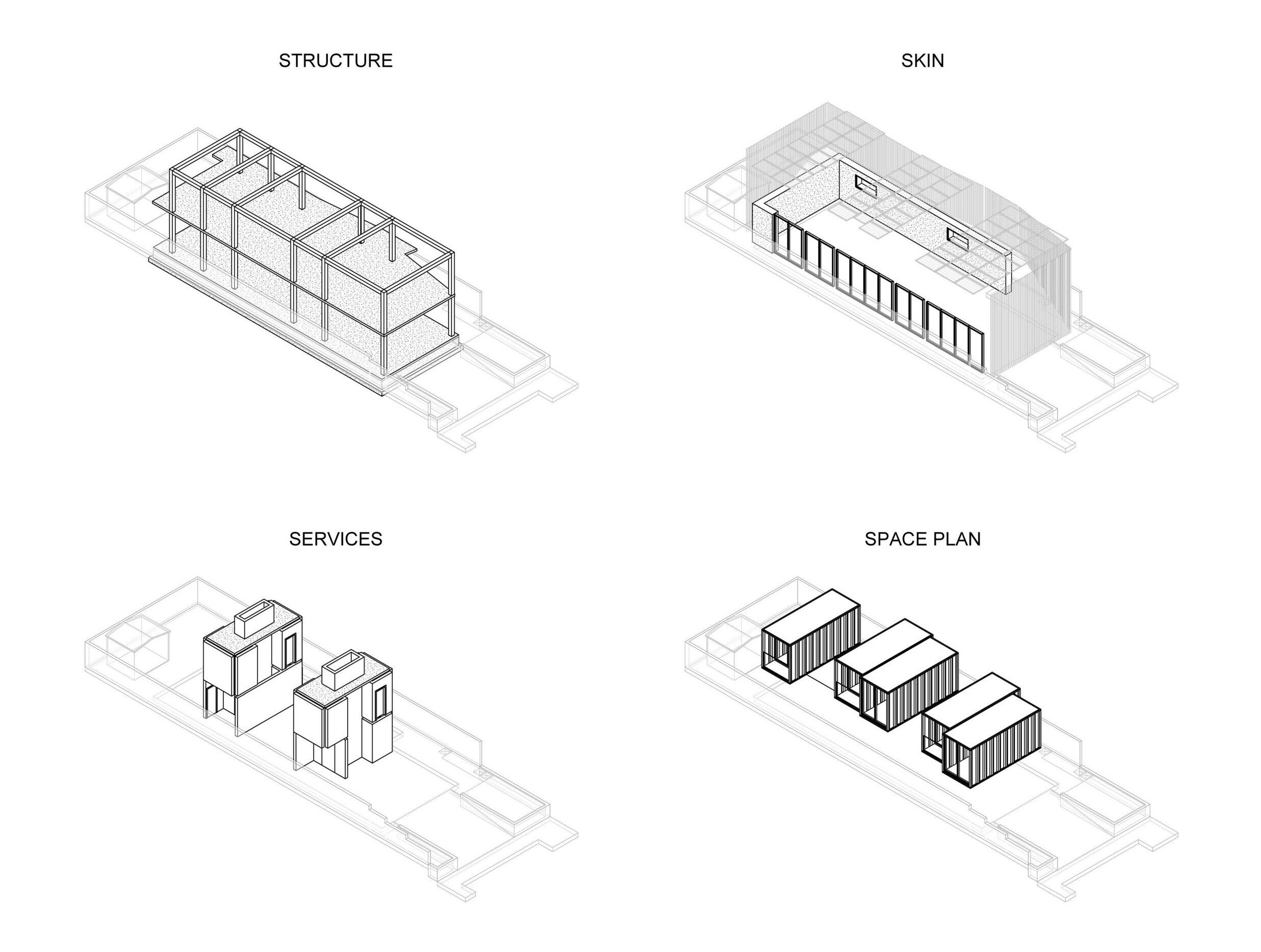

The extracted results from this thesis demonstrate that building assemblies are simply layers of different material longevities and that by converging these layers into monolithic assemblies of high thermal mass materials, material and energy use can be dramatically improved in buildings. One might now ask what this could mean at the overall building level. Should building system layers– the structure, skin, and services– also be integrated, for example? Given the rates of change in buildings from a material, social, economic, and technological point of view, it might make more sense to allow building systems to independently “pulse” or oscillate with changing conditions. Pulsing can enable buildings to dynamically adapt to external feedback reinforcements which Christopher Alexander argues architecture seriously lacks. Using the visual methodology developed in this research, speculative pulsing diagrams above show the possible behavior of different building systems based on hypothetical changes in building requirements (See Odum 2001, 64 for pulsing in natural systems and Geltner et al. 2014, 94-98 for pulsing in real estate markets as a results of property life cycles and building depreciation).

The building structure and skin most likely need to be made of robust longer-lived materials such as concrete, steel, stone, masonry, earth, or even mass timber followed by the shorter-lived services and space plan which can be made of lighter metals, plastics, woods, foams, or composite materials. Regardless of a material’s durability and relative “permanence,” each building layer should employ reversible and easily accessible connections that allow for future change and adaptation. This relates to the fundamental principles of open dynamic systems and to the emergy methodology. As material recycling becomes more prevalent in the future, buildings and cities can act as living organisms driving the metabolism of urbanization around the globe in more economically and ecologically sustainable ways. Developments in the emergy methodology, in this case, can provide a broader and more accurate understanding of the role of energy and material transformation in the built environment. Furthermore, it is essential to consider here what this might all mean for the actual design of buildings.

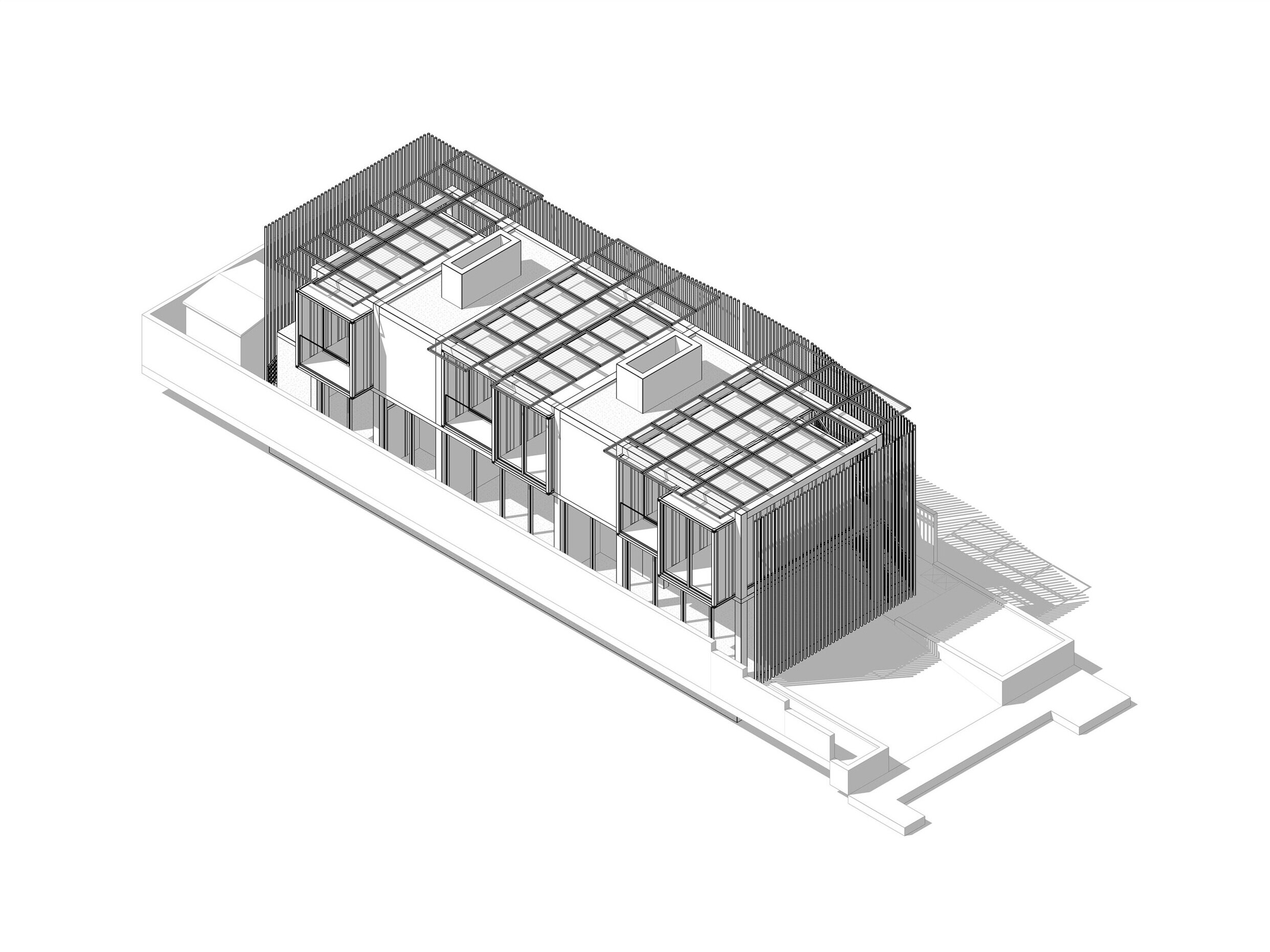

Adaptive Building Designs

Layering different building systems implies more flexible building programs and typologies. If the building skin and space plan are decoupled and free to act independently from one another, for example, then the organization of interior functions and exterior forms need certain levels of adaptability. Stewart Brand suggests designing simple geometric forms with generic programs that enable greater flexibility and adaptation to occur over time (Brand 1994, 181 and 192). A similar approach above was taken in a speculative and conceptual redesign of the Sehovic house using the research presented in this thesis.

This basic approach entailed designing a steel or mass timber structural system using the dimensions of a standard shipping container (8 ft x 9 ft x 20 ft) which could be added to the upper levels of the residence for extra space. Thick earthen walls using construction techniques developed at the California Institute of Earth Architecture wrap the ground floor level acting as a monolithic thermal mass skin. Masonry service cores that contain all the wet spaces (bathrooms, kitchen, etc.) and ventilation shafts divide the interior ground floor and rise through the building to connect to the rooms above. Lightweight and moveable interior partitions further subdivide interior space as user functions change. Solar panels on the roof shade the building and generate electricity while an exterior wooden screen wraps the upper level providing additional shading, privacy, and a soft unifying appearance to the different building elements that can be easily adapted over time. The idea behind this design is to provide maximum flexibility between the different building layers by making them modular and disassemblable for material recovery at any point in time. This type of design approach can also have specific implications for the practice of architecture by integrating design requirements and creating new possibilities for architects.

Conclusion

This thesis questions conventional concepts in architectural design as well as common construction strategies by using life cycle assessment (LCA), energy modeling, and a material recovery potential index (MRPI) to evaluate how different building assemblies use material and energy over time. Three existing facade assemblies and two buildings were tested for material embodied energy, operational energy use, and material recovery potential. Results reveal that by converging lightweight multi-layered building assemblies into monolithic assemblies that use high thermal mass materials, material and energy use can be dramatically reduced in buildings improving overall natural resource productivity.

This also suggests architects can realize much greater agency over larger-scale social and ecological process by not only designing individual buildings but by also designing the actual process of building. In addition to the massive amounts of matter, energy, and information that many architects unwittingly design with every day, it is critical to remember that the decisions architects make have no less of an impact on the geographic, political, economic, cultural, and psychological dynamics of humanity at a variety of scales. It should be the responsibility of an open-minded architect to look beyond mere architectural aesthetics and to recognize that his or her agency lies in not just designing static objects in the landscape but also in designing dynamic flows of matter and energy that have the potential to transform entire built and natural environments.

Future work could expand on this study by analyzing different thermal mass materials such as brick, stone, masonry, earth, and even mass timber while evaluating their impacts on system adaptability at the building scale. Investigating the economic benefits, regulatory constraints, large-scale socio-ecological impacts, and new architectural practice models could also reveal promising opportunities within these alternative design strategies.

As long as buildings and cities continue to impact social and ecological systems at a global scale, the decisions architects make will play a central role in determining the development, and possibly fate, of society in the years to come.

—————————————

REFERENCES

Abramson, D. (2016). Obsolescence : An architectural history. Chicago ; London: The University of Chicago Press.

Arch Daily. 2019. “Quinta Monroy Elemental.” Accessed May 14.

Arch Daily. 2019. “Villa Verde Elemental.” Accessed May 14.

Barkow Leibinger. 2019. “Smart Material House.” Accessed April 21.

Brand, S. (1994). How buildings learn: What happens after they're built. New York, NY: Viking.

Building Science Corporation. 2019. “Residential Wall Construction.” Accessed May 14.

California Institute of Earth Architecture. 2019. “CalEarth.” Accessed May 9.

Cappelli, F., Delogu, M., Pierini, M., & Schiavone, F. (2007). Design for disassembly: A methodology for identifying the optimal disassembly sequence. Journal of Engineering Design, 18(6), 563-575.

Clapham, M., Foo, S., Quadir, J., Meadows, D., Bennett, A., & Dean, S. (2008). Development of a Canadian National Standard on Design for Disassembly and Adaptability for Buildings. Journal of ASTM International, 5(2), 101061.

Crowther, P. (2016). Morphological Analysis Of The City For Achieving Design For Disassembly. WIT Transactions on Ecology and the Environment, 204, 15-26.

Diaz, S.. Settele, J., and Eduardo Brondizio, 2019: Summary for policymakers of the global assessment report on biodiversity and ecosystem services of the Intergovernmental Science-Policy Platform for Biodiversity and Ecosystem Services. Global Assessment Report on Biodiversity and Ecosystem Services. May 6.

Emergy Society. 2019. “Emergy Database.” Accessed May 8.

Empire State Realty Trust. 2019. “Empire State Building Fact Sheet.” Accessed April 25.

Fernandez, J. (2002). Diversified Longevity: Orchestrated Obsolescence for Intelligent Change. Thresholds, (24), 12-19.

Geltner, D., Miller, N., Clayton, J., & Eichholtz, P. (2014). Commercial real estate : Analysis and investments (3e. ed.). Mason, OH, USA: OnCourse Learning.

Global Alliance for Buildings and Construction, Global Status Report 2017.

Hoegh-Guldberg, O., D. Jacob, M. Taylor, M. Bindi, S. Brown, I. Camilloni, A. Diedhiou, R. Djalante, K.L. Ebi, F. Engelbrecht, J.Guiot, Y. Hijioka, S. Mehrotra, A. Payne, S.I. Seneviratne, A. Thomas, R. Warren, and G. Zhou, 2018: Impacts of 1.5ºC Global Warming on Natural and Human Systems. In: Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty [Masson-Delmotte, V., P. Zhai, H.-O. Pörtner, D. Roberts, J. Skea, P.R. Shukla, A. Pirani, W. Moufouma-Okia, C. Péan, R. Pidcock, S. Connors, J.B.R. Matthews, Y. Chen, X. Zhou, M.I.Gomis, E. Lonnoy, T.Maycock, M.Tignor, and T. Waterfield (eds.)]. In Press.

Jeandin, & Mascle. (2016). A New Model to Select Fasteners in Design for Disassembly. Procedia CIRP, 40, 425-430.

Kieran, S., Timberlake, J., & KieranTimberlake. (2011). Cellophane House: KieranTimberlake. Philadelphia: KieranTimberlake.

KieranTimberlake. 2019 “LivingHomes KT.” Accessed May 13.

KieranTimberlake. 2019 “Loblolly House.” Accessed April 21.

Kieran, S., & Timberlake, J. (2004). Refabricating architecture : How manufacturing methodologies are poised to transform building construction. New York: McGraw-Hill.

Matos, G., (2017) Use of Raw Materials in the United States from 1900 through 2014: U.S. Geological Survey (USGS). Fact Sheet 2017–3062.

Mayer, M., & Bechthold, M. (2017). Development of policy metrics for circularity assessment in building assemblies. Economics and Policy of Energy and the Environment, 2017(1), 57-84.

Moe, K. (2013). Convergence : An architectural agenda for energy. London: Routledge, Taylor & Francis Group.

Odum, H. (1996). Environmental accounting : EMERGY and environmental decision making. New York: Wiley.

Odum, Howard T. “Material circulation, energy hierarchy, and building construction.” In Construction Ecology: Nature as the Basis for Green Buildings, edited by Charles J. Kibert, Jan Sendzimir, and G. Bradley Guy, 37-71. London: Routledge, 2001.

Pulselli, R.M., Simoncini, E., Pulselli, F.M., & Bastianoni, S. (2007). Emergy analysis of building manufacturing, maintenance and use: Em-building indices to evaluate housing sustainability. Energy & Buildings, 39(5), 620-628.

U.S. EPA, Buildings and their Impact on the Environment: A Statistical Summary 2009.

Yi, Srinivasan, Braham, & Tilley. (2017). An ecological understanding of net-zero energy building: Evaluation of sustainability based on emergy theory. Journal of Cleaner Production, 143, 654-671.

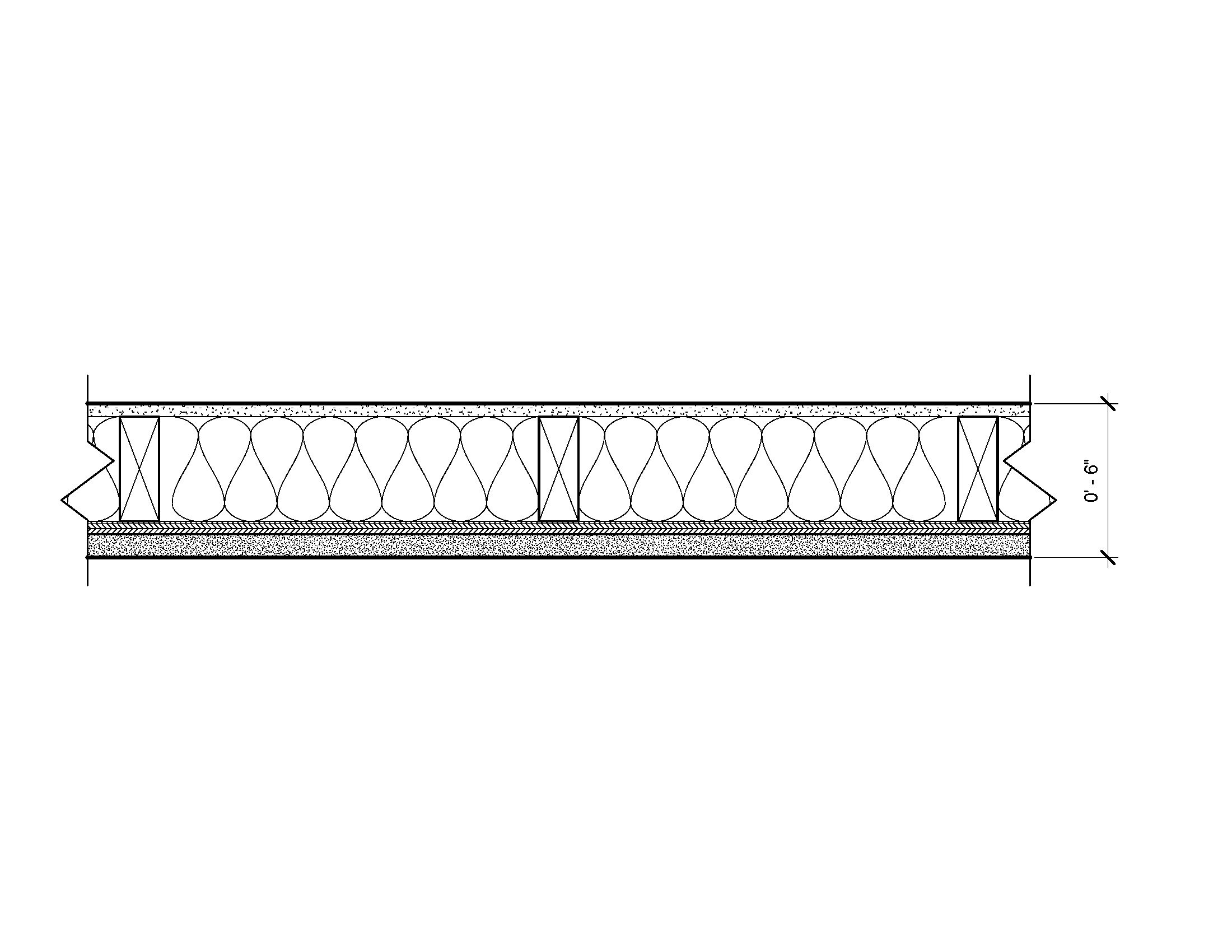

Appendix 1 - Wood Stud Facade Assembly

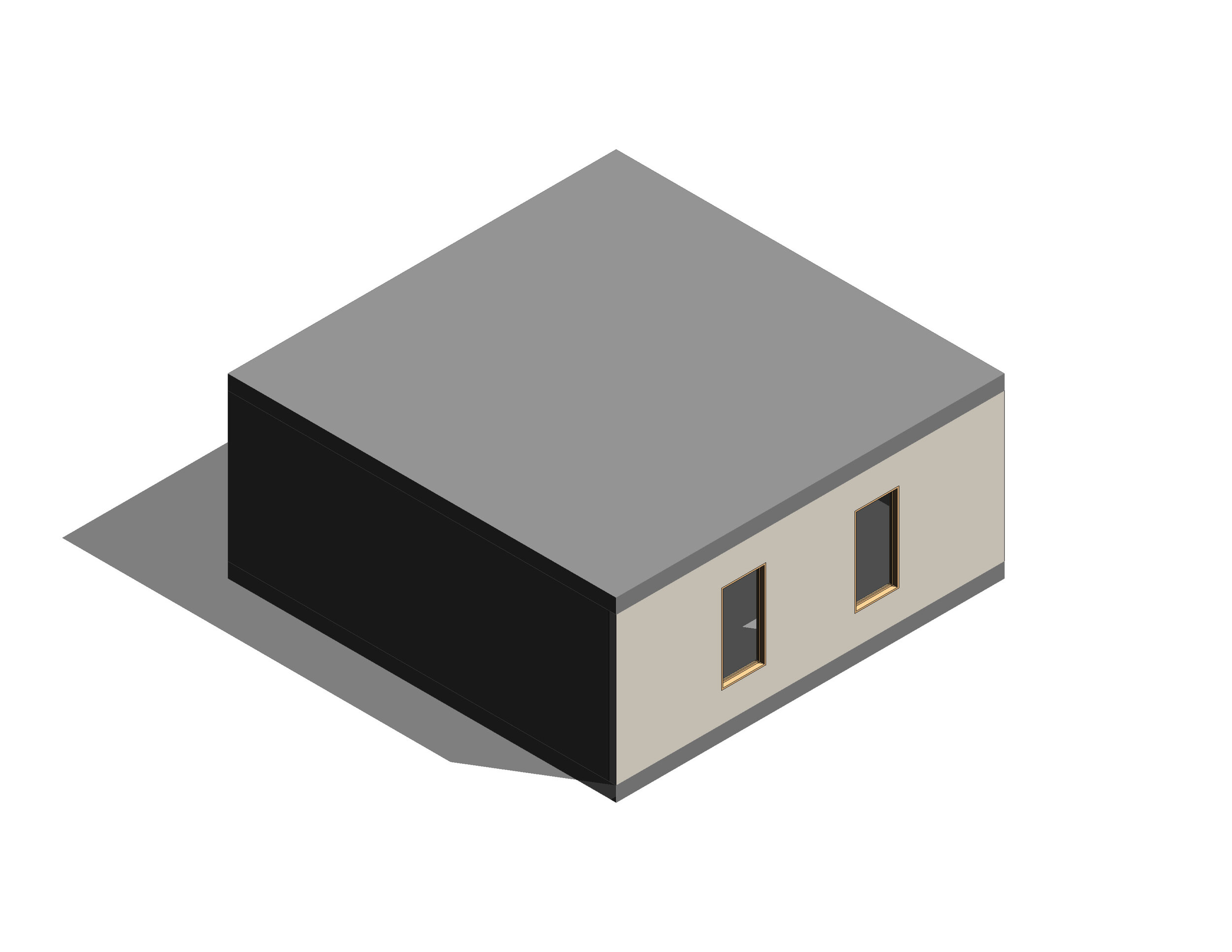

Shoebox 3D model (top) and plan detail (bottom)

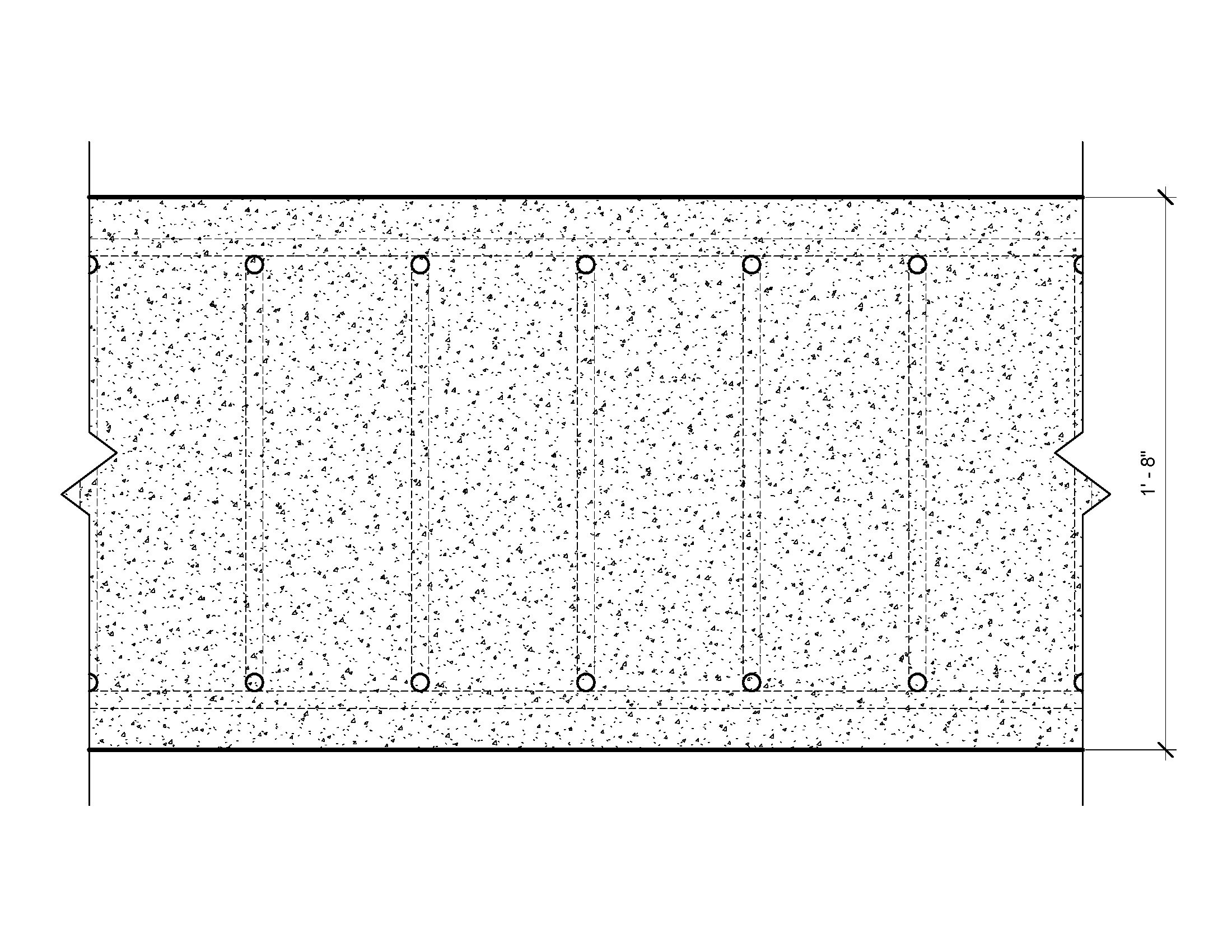

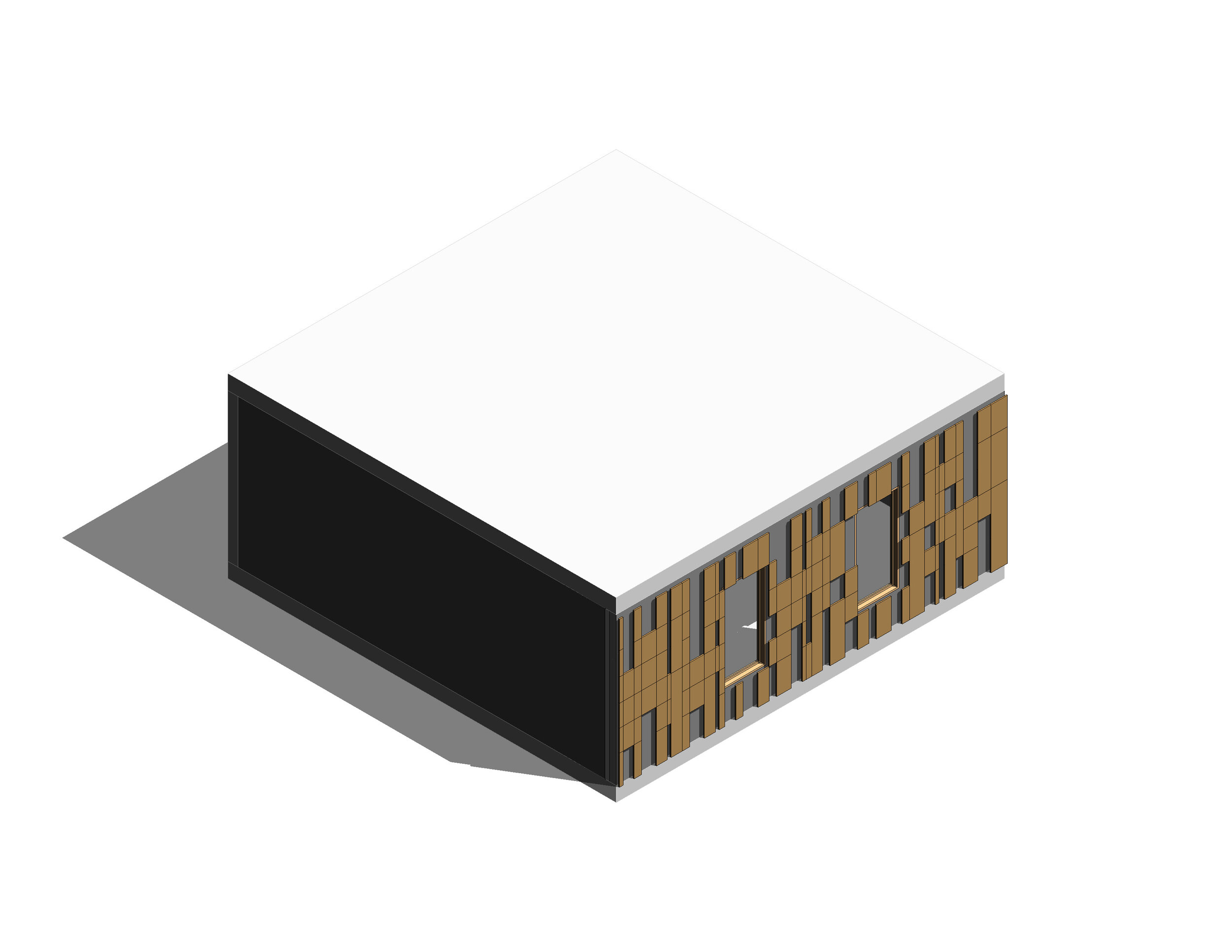

Appendix 1 - Concrete Facade Assembly

Shoebox 3D model (top) and plan detail (bottom)

Appendix 1 - Aluminum Frame Facade Assembly

Shoebox 3D model (top) and plan detail (bottom)

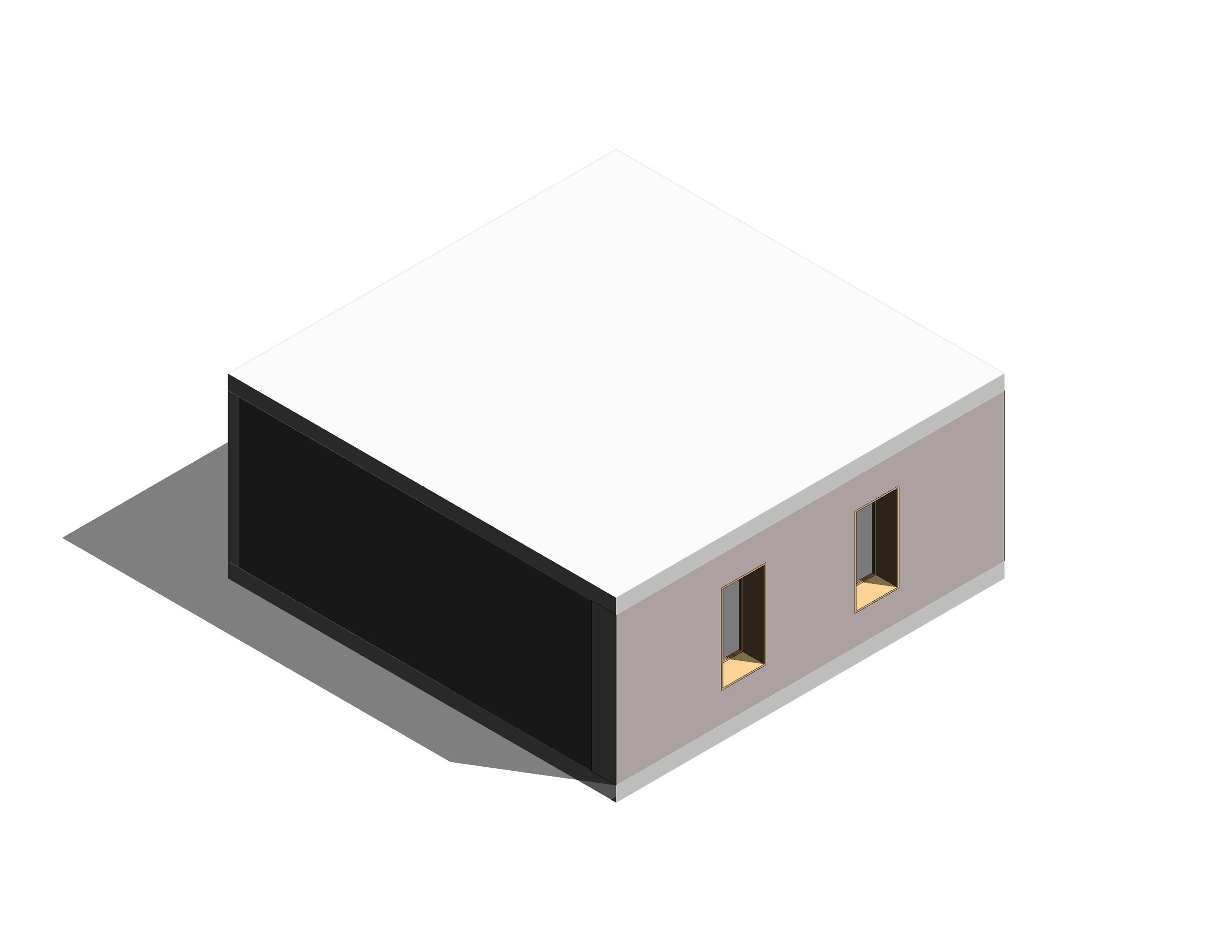

Appendix 1 - Sehovic House

Aerial view of Sehovic house (top); 3D model of existing Sehovic house in wood (middle); 3D model of speculative Sehovic house in concrete (bottom)

Appendix 2

Tally calculation methodology: Life cycle assessment methods (top); Life cycle stages (middle); Environmental impact categories (bottom).

Appendix 3 - DesignBuilder models

Facade “shoebox” building models (top); Existing Sehovic house in wood (middle); Speculative Sehovic house in concrete (bottom).

Appendix 4 - Facade Embodied Energy

LCA and Emergy methodology comparison.

Appendix 5 - Facade Shoebox Building Operational Energy Use

From top to bottom: Simulation inputs and operational energy impacts for each facade shoebox building element; Tabular data of operational energy impacts for each facade shoebox building element; Operational energy use for wood, concrete, and aluminum shoebox buildings.

Appendix 6 - Facade Material Recovery Potentials

Material recovery score breakdowns for concrete, aluminum, and wood facades.

Appendix 7 - House Embodied Energy

Year 1 (top) and year 50 (bottom) wood and concrete house embodied energy breakdowns.

Appendix 8 - House Operational Energy Use

Wood and concrete house operational energy use in Los Angeles and Boston.

Appendix 9 - House Material Recovery Potentials

Material recovery score breakdowns for the concrete and wood house.